The surge in demand for renewable energy solutions has put a spotlight on the critical role of metal fabrication in the development of sustainable technologies. Metal fabrication, a cornerstone of industrial manufacturing, has evolved significantly…

Read More

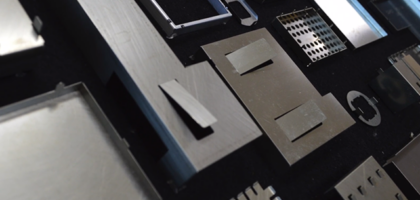

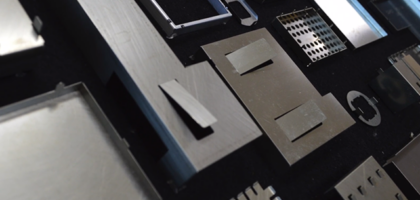

In industries where technological advancements are continually reshaping manufacturing methods, the importance of precision, efficiency, and versatility in the production of thin metal parts has never been greater. Across a broad spectrum of industries, from…

Read More

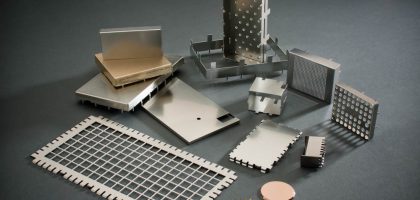

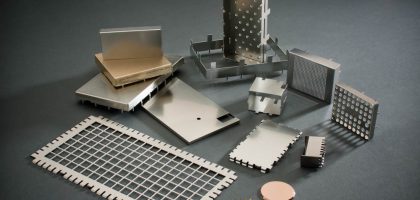

To the average person on the street, it can seem almost miraculous that thin metal parts seen in many different applications can be so intricately and precisely crafted that they look like works of art.…

Read More

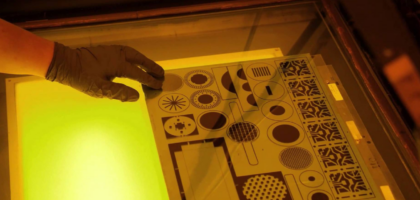

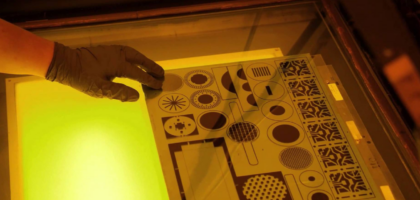

There is no doubt that modern manufacturing has been transformed by the advent of photo chemical etching. Its influence extends across various manufacturing sectors, but it has been particularly transformative in the worlds of electronics,…

Read More

Chemical etching is a process that uses a corrosive agent (called an etchant) to remove unwanted material from a metal sheet, leaving behind a predetermined shape or pattern. It is a versatile and cost-effective production…

Read More

In the realm of metal fabrication, technology continually evolves, giving rise to innovative methods that can craft intricate designs with precision. One such revolutionary technique that has changed the face of metal component manufacturing is…

Read More

Photo chemical etching (also called chemical etching or photo etching) is a remarkable process that has revolutionized manufacturing across various industries. This intricate method of producing precisely designed thin metal parts has not only redefined…

Read More

United Western Enterprises, Inc. is pleased to share that we participated in this year’s Design-2-Part Show in Orlando, FL. The two-day event occurred at the Orange County Convention Center on May 2nd and 3rd, 2023.…

Read More

It happens all the time—manufacturers that are still building up their experience in the industry will talk to more seasoned metal part manufacturers that specialize in EMI shielding, and will learn all about chem etching…

Read More