Dimensions & Tolerances for Photo Chemical Etching

Geometric Dimensioning and Tolerancing (GD&T)—sometimes alternatively called geometric dimensions and tolerancing—is a valuable symbolic language that enables engineers to define the precise geometry of an object to be produced. It also allows manufacturers to dictate the range of geometric tolerances of a given material, which means the various features on a part can be reproduced with a high level of precision.

United Western Enterprises is well versed in the use of GD&T symbols and principles to guide our manufacturing processes and ensure that our client’s design intent is fully realized.

Advantages of GD&T

GD&T was devised in the 1940s as a way of improving on the relatively imprecise tolerancing specifications that were in use up to that time. Prior to the advent of AD&T, tolerance zones were typically XY squares. GD&T introduced circular tolerance zones, which were more accurate. This innovation sharply reduced the incidence of false negatives and, by doing so, improved the efficiency of manufacturing processes.

Today, GD&T is an internationally recognized system. It gives the designer flexible symbolic tools to establish exact geometric tolerances in form, profile, orientation, location, and run-out, in a way that is easily interpreted by the different participants in the supply chain.

Why UWE?

Since our founding in 1969, UWE, Inc., has earned a reputation as a leader in the field of metalworking. We can handle a wide range of material thicknesses, although your production requirements may limit your viable options. An AS 9100D / ISO 9001:2015 Certified Company, we operate out of a 21,000-square-foot building in Camarillo, California. Feel free to contact us with your questions about our services.

Here at United Western Enterprises we pride ourselves on doing our best to support our customers and enable them to receive the best parts possible. Here are a few guidelines to designing your parts with our process in mind.

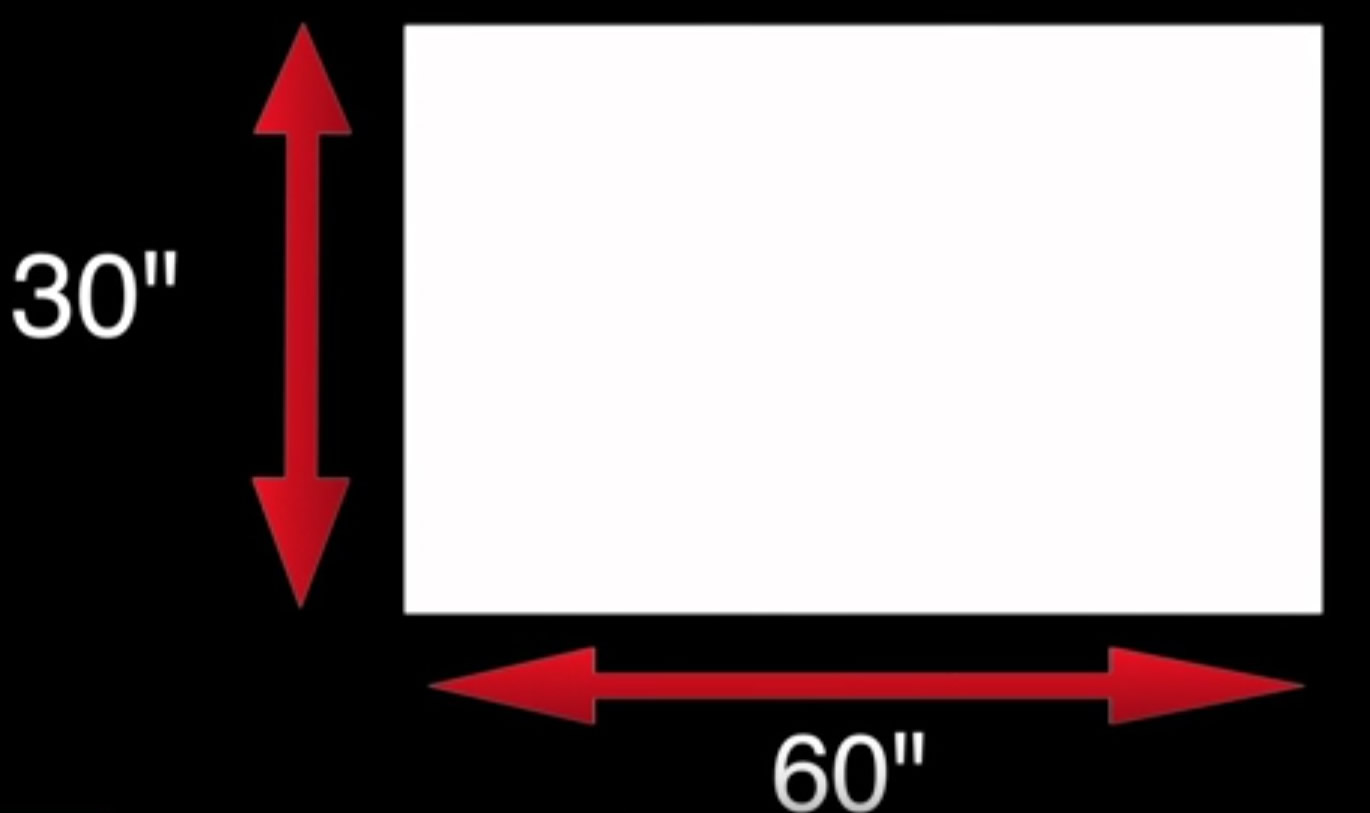

One of the first things to consider is the size of the part. For our processing the overall size of the part cannot be larger than thirty inches wide and 60 inches long.

Our ability to make a part this large will depend on a few other factors; for instance how thick the material is and how tight the requested tolerances are.

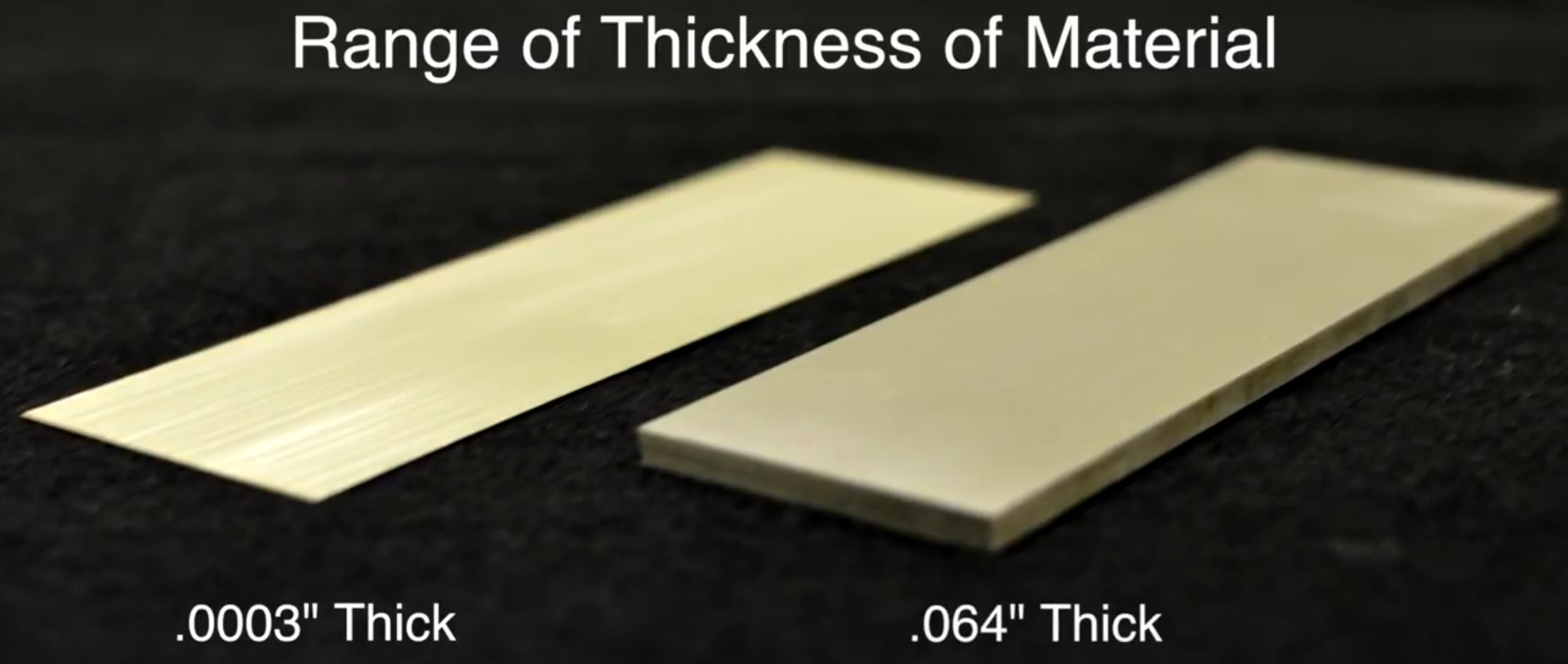

Next we should talk about how thick the material can be. If we are etching all the way through the material our range of thickness is generally .0003” thick to .064” thick.

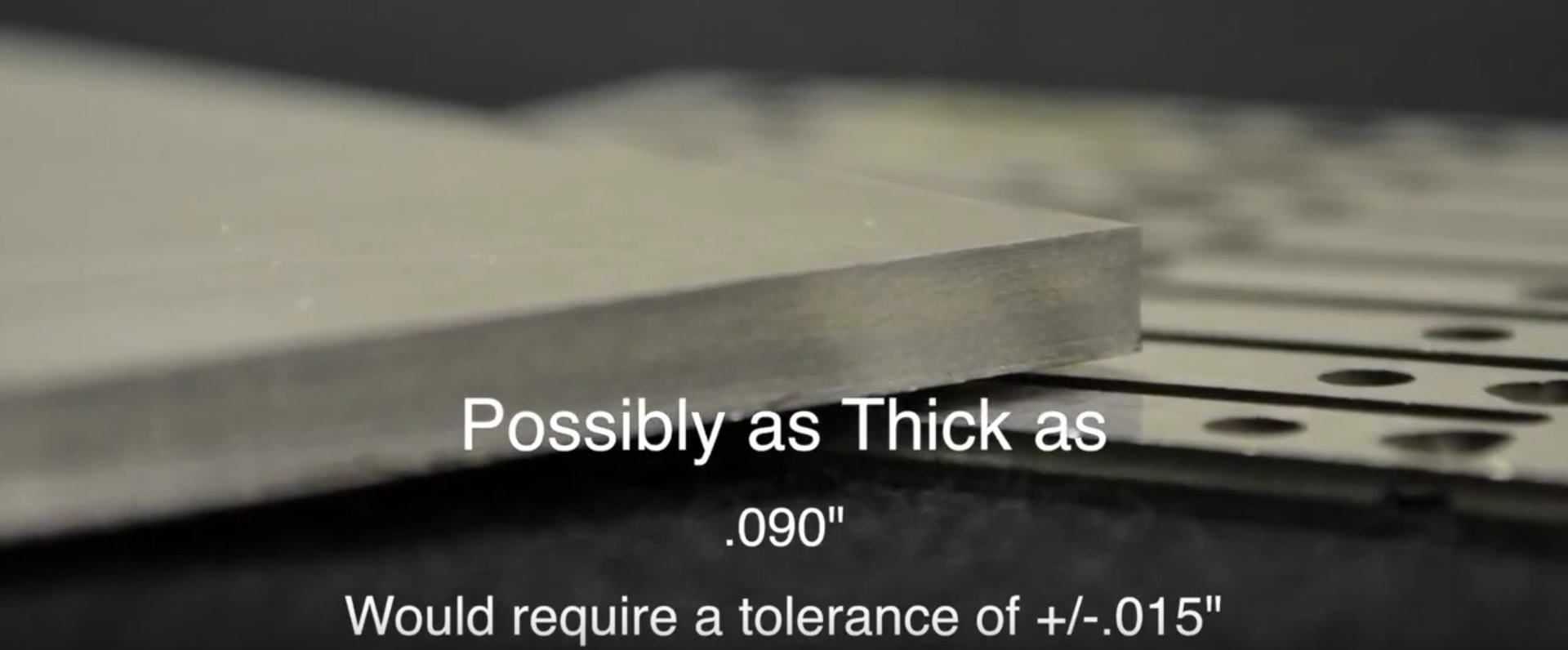

On occasion we have made parts as thick as .090” thick however parts that thick would require a tolerance of approximately .015” as well as a few other considerations.

If the requirement is to just etch down or engrave characters into material our equipment can handle material as thick as .250”.

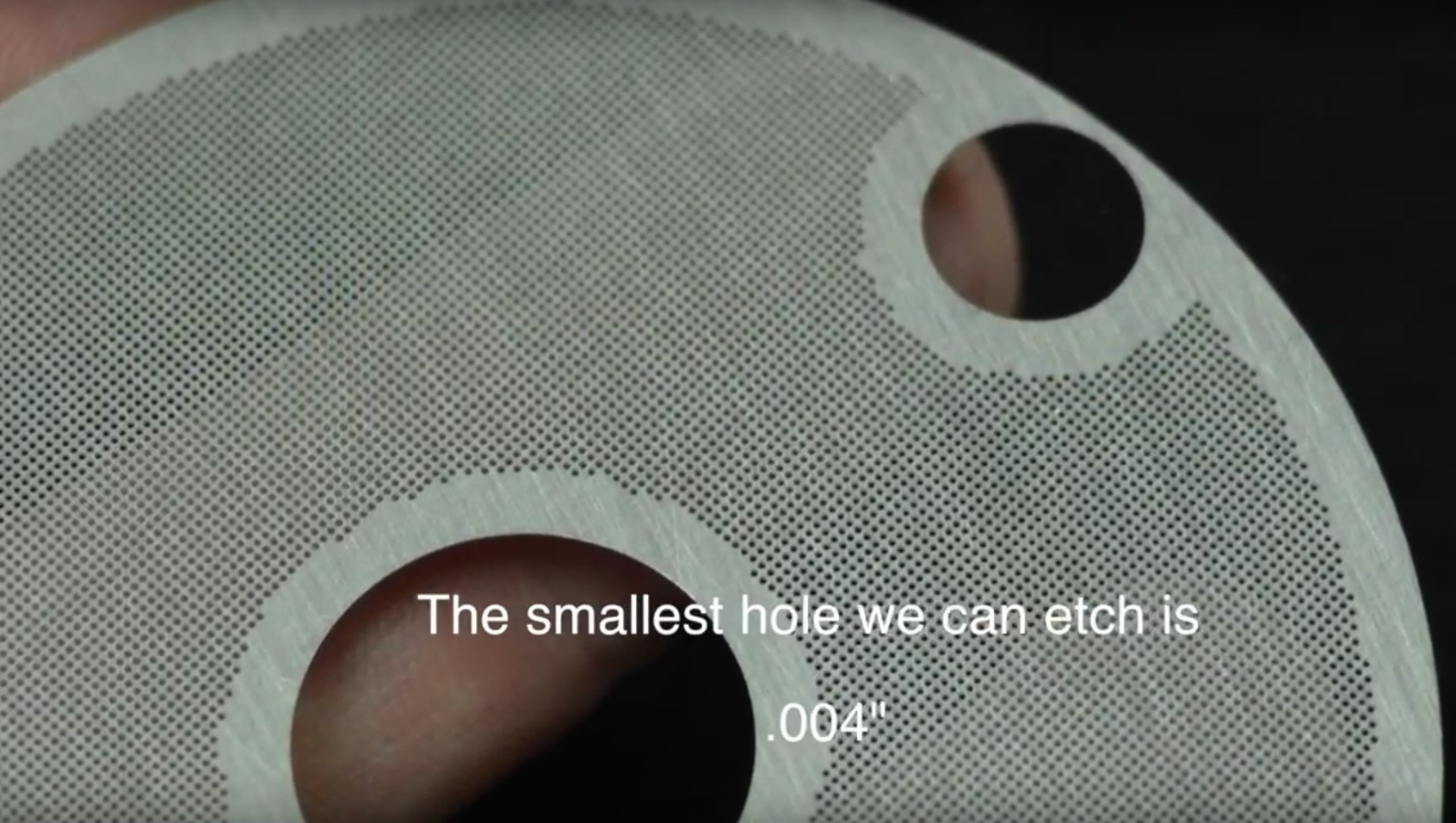

The smallest hole we can etch is dependent on how thick the base material is. The general rule is we cannot etch a hole, slot or any opening that is smaller than the material thickness. In the case of very small material, the smallest hole we can etch is .004”.

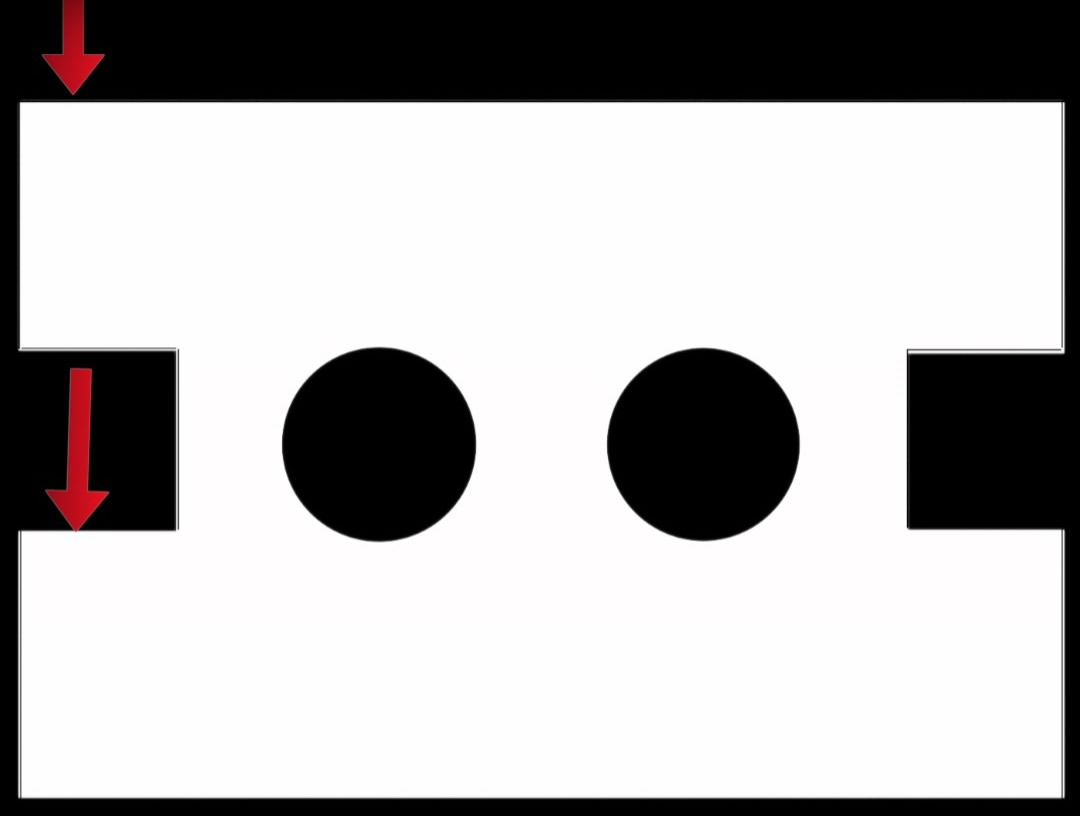

The minimum distance between holes, or web is also a function of the material thickness. Our experience allows us to create parts with a remaining web of as little as 67% of material thickness. So for instance for a part made of .010” thick material we can have remaining material of as little as .007”.

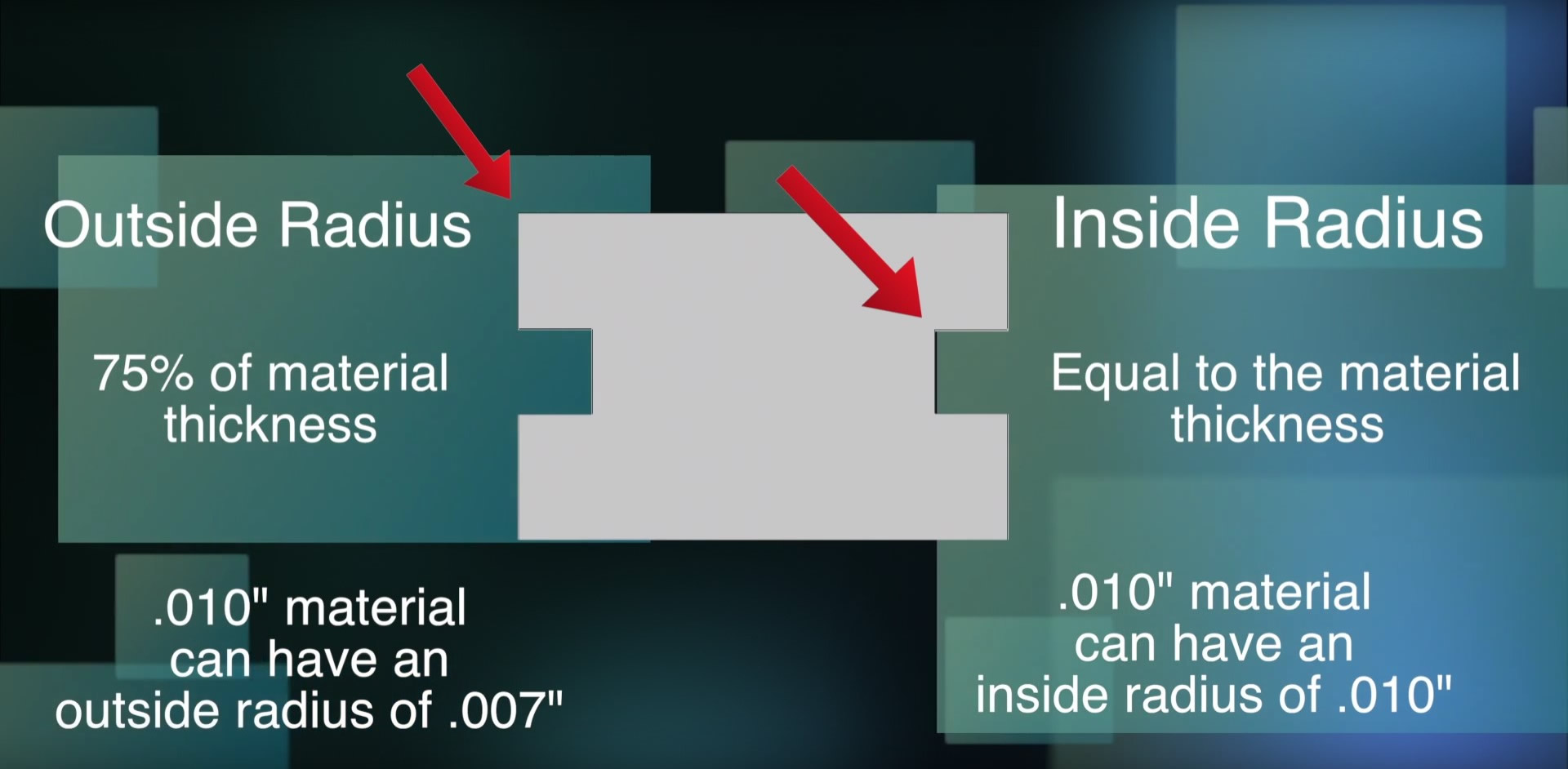

Material thickness also has an effect on the minimum radius we can create. For an outside radius we can generate a radius that is 75% of the material thickness. So on material that is .010” thick we can achieve a radius that is .007”. The tightest inside radius we can achieve is equal to the material thickness. So for the same .010” thick material we would be able to create an inside radius that is .010”. Better results are possible with special considerations.

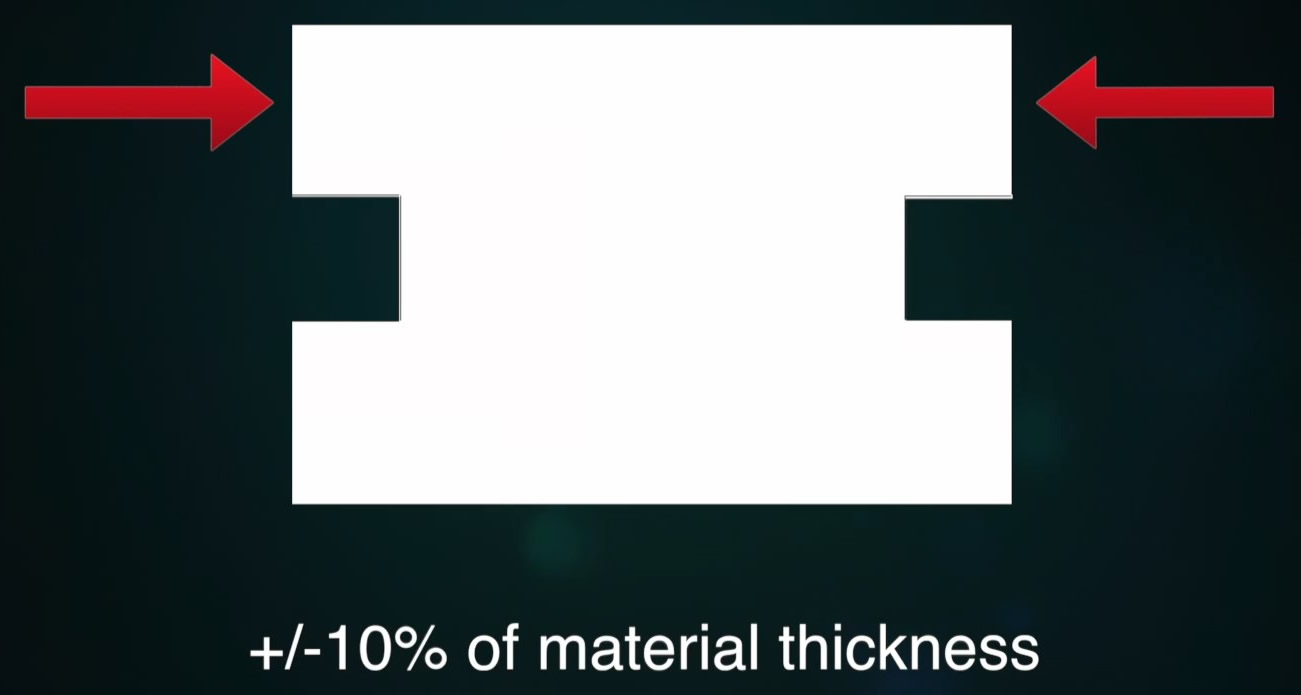

Tolerances are also driven in a large respect by material thickness. As a rule on edge to edge dimensions we can hold a tolerance of +/- 10% of material thickness.

This would correspond to the tightest tolerance requirement for a given part. For all other edge to edge tolerances we would ask for +/-15% of the material thickness. A few exceptions to this rule could apply. For instance the diameter of a hole can be reamed to size as a secondary operation. Also for characteristics we call “like edges”, tolerances can be held much tighter

.

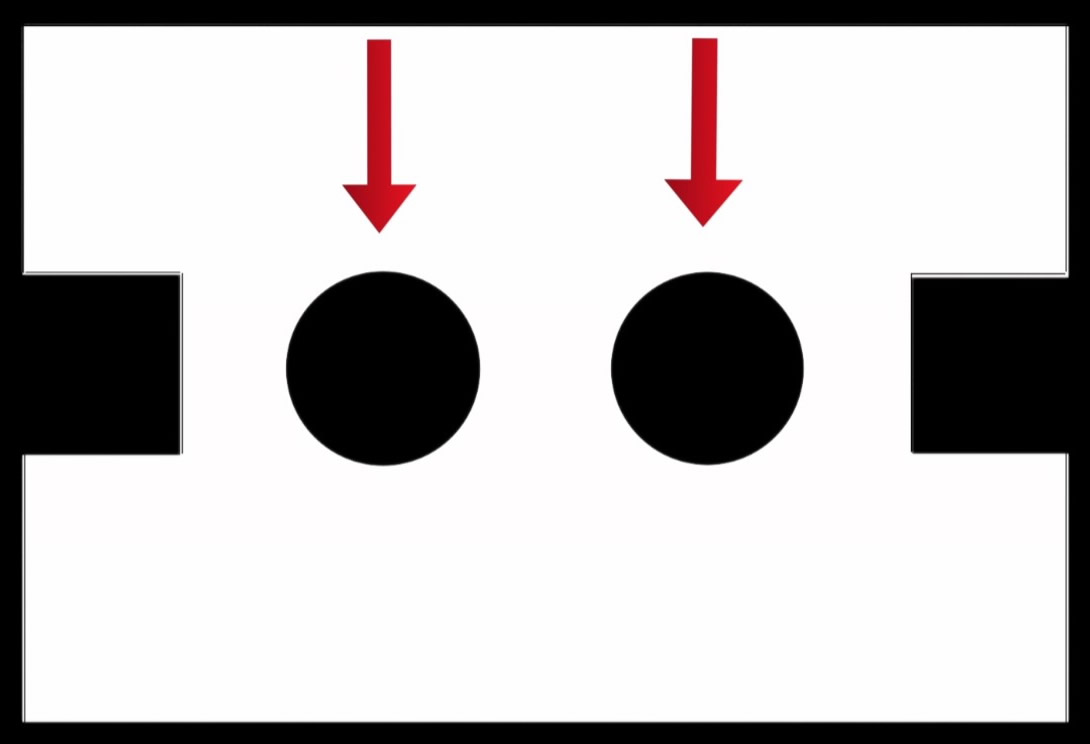

The tolerances for center to center dimensions can be held to .0005” no matter what the material thickness is.

This is because that dimension is established in the tooling for the part and is not determined by how long the part etches.

These are a few general guidelines that can be used when considering chemical etching. If you have any questions please feel free to email us at sales@uweinc.com or call us at (800)964-6461. We look forward to helping you design the part you need.