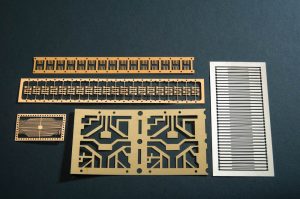

Electroplating Services for Precision Machined Parts

Give your parts an extra layer of protection with metal plating from UWE.

United Western Enterprises is pleased to offer a full range of metal plating services through our network of world-class electroplating specialists. As one of our value-added services, our metal plating capabilities can help make UWE your one-stop solution for both parts manufacturing and finishing.

About Metal Plating

Metal plating applies a thin outer layer of metal to a substrate material to improve durability and, in some applications, visual appeal. This plating solution is usually performed through an electroplating process; however, electroless chemical processes also exist.

Typically, the choice of metal used for metal plating depends on the eventual application. Tin plating, for example, helps prevent corrosion and spoilage in canned food, while EMI shielding utilizes several types of plating to protect electronic components for electromagnetic interference.

Below we’ll review some of the most common types of plating techniques and materials, and why they are used.

Nickel Plating

Nickel electroplating is among the most widely used types of metal plating, finding use in everything from electronics to automobiles. In electronics applications, nickel plating helps protect components from corrosion and short circuits while also increasing strength and solderability. Nickel plating is also found on coinage, automotive trims, and in many other applications.

Tin Plating

Tin’s excellent solderability and corrosion resistance has made it the preferred choice for numerous applications, with more than half of all tin being used for soldering applications. Some of the most common applications of tin plating include food service, aerospace, and electronics components, such as tin-plated steel for EMI shielding.

Copper Plating

Copper’s high conductivity makes it ideal for electrical applications, specifically circuit components and other electronics. Copper electroplating is also used to improve corrosion resistance in industrial components such as pipe couplings and underplating.

Silver Plating

Boasting even greater conductivity than copper, silver is a highly sought-after metal finishing for electrical connectors and other electronic components where conductivity is crucial. Silver’s lustrous appearance and comparatively lower cost than gold has made it a common plating material for jewelry and dinner utensils.

Gold Plating

Gold plating shares many of the same applications and benefits as silver plating, only with a slightly higher conductivity and differing appearance. However, these qualities are still highly sought after from electronic components to jewelry.

Anodizing

While not technically a type of metal plating, anodizing uses similar methods employed in metal plating to convert a metal surface into an anodic oxide. Typically used as a form of aluminum plating, the anodizing process helps improve the durability and appearance of a metal without having to apply a separate layer of metal.

Chem Film

Chem film uses a process known as “chromate conversion” to protect metals (usually aluminum) from corrosion. Unlike metal plating or anodizing, chem film utilizes a chemical coating to increase corrosion resistance rather than a separate metal or oxide layer.

Advantages of Metal Plating

While the advantages of metal plating depends on the metal and its application, the main advantages generally include:

- Corrosion and wear resistance

- Extra durability and hardness

- Reduced cost for applications and alloys of precious metals

- Improved conductivity

- Improved solderability

- Improved adhesion for paint and other coatings

- Improved appearance and aesthetic appeal

Why Choose United Western Enterprises?

With over 100 years of combined experience, the United Western Enterprises team has manufactured thin metal parts for industries ranging from medical to aerospace and automotive to electronics. Our team is also capable of rapid prototyping and extensive consultation to ensure that you get the right parts and make the right decisions for your industry.

We specialize in the use of aluminum alloys, beryllium copper, copper alloys, nickel and nickel alloys, nickel silver, and stainless steel alloys. In addition to plating solutions, we offer a range of value added services, including metal forming, heat treating, and laser welding.

For more information on our services or to request a quote, call our sales team at (800) 964-6461 or email us at sales@uweinc.com. We look forward to assisting you as your go-to photochemical etching specialists!