Photochemical Etching Services | Automotive Industry

Customers trust United Western Enterprises, Inc. for photo chemical etching services in many different industries that require thin metal parts. Precision, quick turnaround time, and AS9100D & ISO 9001 certification are just some reasons we are so popular in this segment. Since 1969, we have been providing photo etching for the engineering industry and creating products for use in the electronics, aerospace, medical, and automotive sectors.

All in the Details

We benefit customers in two key areas—dimensions and tolerance. Able to process parts as large as 30” wide and 60” long, our process can etch through material from .0003” to .064” thick. Holes as small as .004” can be created as well, and we can achieve a radius 75% of the material thickness. Our process enables us to maintain high precision with an edge-to-edge dimensional tolerance of ±10% of material thickness and center-to-center tolerance of .0005”.

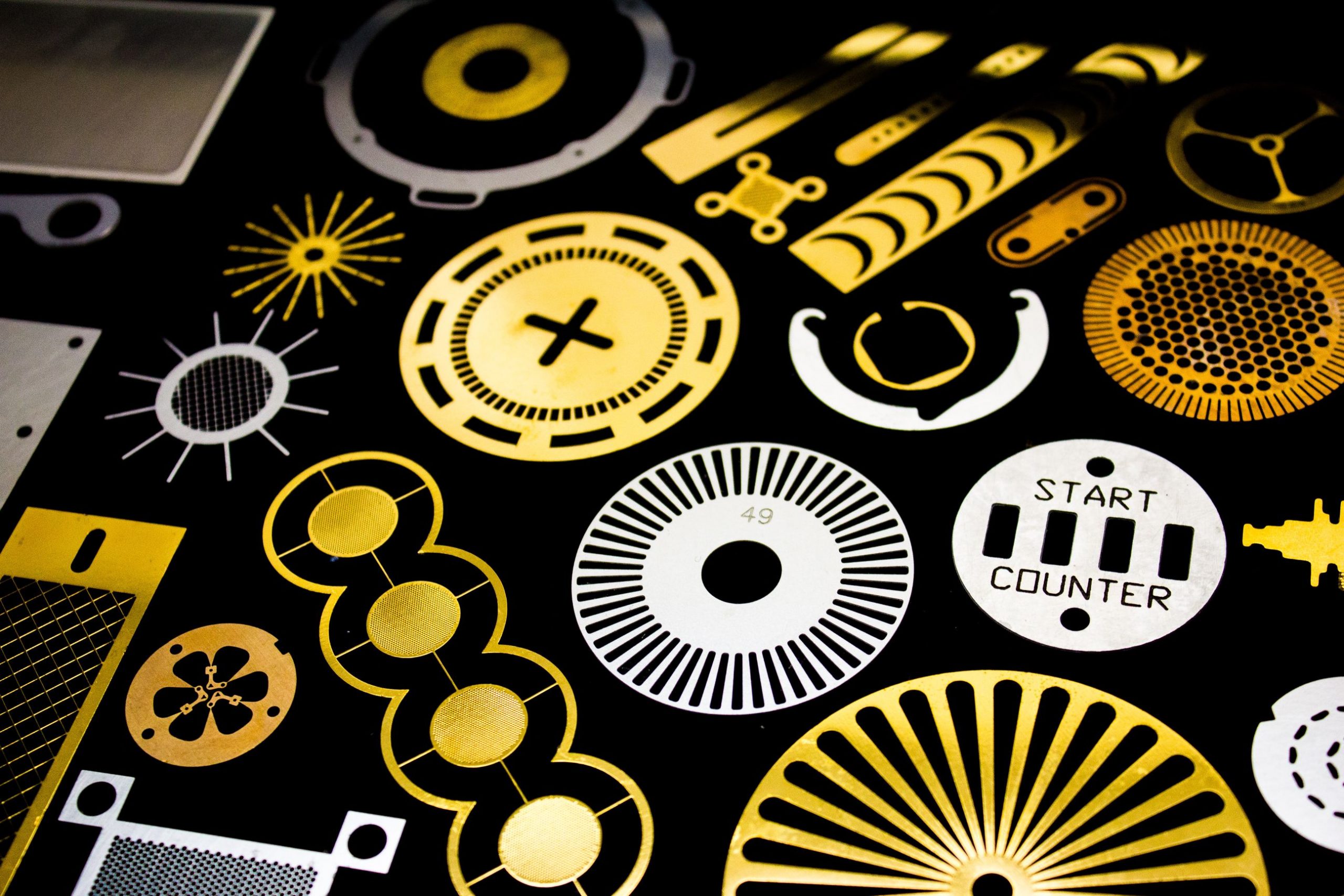

That’s not all. We can produce EMI/RFI shielding for small electronic components. Speaker grilles, antennas, nameplates, gaskets, shims, washers, heat sinks, and burr-free GDI flexures are other parts we can make quickly and economically. We can also chemically etch fuel pump and ABS braking components with relative ease.

Parts and Metals

UWE, Inc. specializes in manufacturing small metal components that are burr free and produced with a stress-free process that allows for tight tolerances and high quality. From EMI and RFI shields to shims made of brass, copper, steel, aluminum, or bronze, the limits are few when it comes to producing parts without any deformations or imperfections. We photo etch apertures, optical components, encoder disks, springs and contacts, fine screens, and covers and lids as well.

In addition, we provide photo chemical etching services for custom thin metal parts. Our ability to work with many types of metals helps as well. Whether it’s connectors or contacts, springs, air intake grilles, or heat exchangers, we offer several options for customers in the automotive sector. We can chemically machine:

- Aluminum alloys

- Copper alloys

- Beryllium copper

- Nickel/nickel alloys

- Stainless steel alloys

Rely on UWE, Inc. for Precision Metal Components

Our photo chemical etching process allows us to create precise components of any order size, and to provide unique prototyping services for our customers. High-quality parts are more readily available to customers in the automotive industry through our enterprise.

United Western Enterprises, Inc. is prepared for the production of standard and custom components. To learn more about our services and process, and chemical etching for automotive customers, request a quote or call us at (800) 964-6461 today.