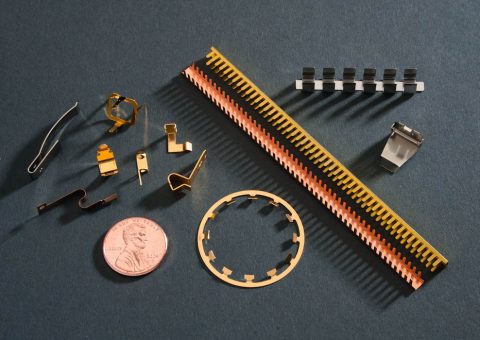

Micro Contacts & Custom Springs | Photochemical Etching

United Western Enterprises can produce your parts to suit your application and space requirements. Our experience with springs and contacts enables us to make parts to your specifications. Thanks to our in-house forming capability, first articles can be delivered quickly. If an adjustment to the design is required after the first article is delivered, it can usually be done easily and quickly with a small non-recurring engineering charge.

We can produce various types of springs and contacts, including contact membranes, spring finger contacts, resistive heating elements, and battery contacts. Battery tabs that can be soldered and welded can be produced to your design specifications. Using our photo etching process, we can integrate custom tabs, holes, and notches; single/dual style leaf springs; clip-on/board-mounted battery contacts; and many other parts in prototype and production quantities.

Typical Applications

- Electronic equipment: Everything from home appliances to antennae, to PCB contacts.

- Medical equipment: Etched springs/contacts can endure the harsh conditions within the human body.

- Military and aerospace: Contact springs used in military jets and durable connectors for space satellites.

Materials

Photoetched parts are extremely reliable, have a low coefficient of thermal expansion, and an excellent strength-to-weight ratio. They are dependable in the most extreme environments.

Produced in thicknesses down to a fraction of the diameter of a human hair, precision springs and contacts can be made of materials such as:

- Spring Steel

- Stainless Steel

- Phosphor Bronze

- Beryllium Copper

Heat treating beryllium copper increases hardness. We also offer plating services; with nickel or gold plating, we can add corrosion resistance, while gold improves conductivity as well.

Tell Us Your Requirements

United Western Enterprises employs an extremely precise and flexible photochemical etching process and can produce a wide range of parts at tight tolerances. To discuss your requirements with us, call (800)964-6461 today or request a quote with all the details of your order.