Photochemical Etching Services | Electronics Industry

High precision and reasonable costs are essential in today’s electronics market. We provide photochemical etching for electronics companies requiring precision and a quick turnaround time, thanks to our commitment to meeting customers’ expectations while sticking to tight delivery schedules.

All in the Details

In the electronics industry, precision metal parts are crucial because small dimensions and tight tolerances are typical. We can produce parts as large as 30” wide by 60” long. However, Etched material can be from .064” thick to as thin as .0003”.

With the high-precision capabilities of our equipment, we are capable of:

- Tolerances of about +/-.015” for parts as thick as .090”.

- Etching or engraving of materials up to .250”.

- Holes as small as .004” for extremely small materials.

- Creating parts with a web down to 67% of the material thickness.

- Generating an outside radius of 75% of the material thickness.

Material thickness is a major factor in determining tolerances. In general, a tolerance of +/- 10% applies to edge to edge dimensions. If the tightest tolerances aren’t demanded, a +/-15% tolerance for thickness is attainable, while center to center dimensional tolerances can be maintained at 0.0005” no matter the thickness of the material.

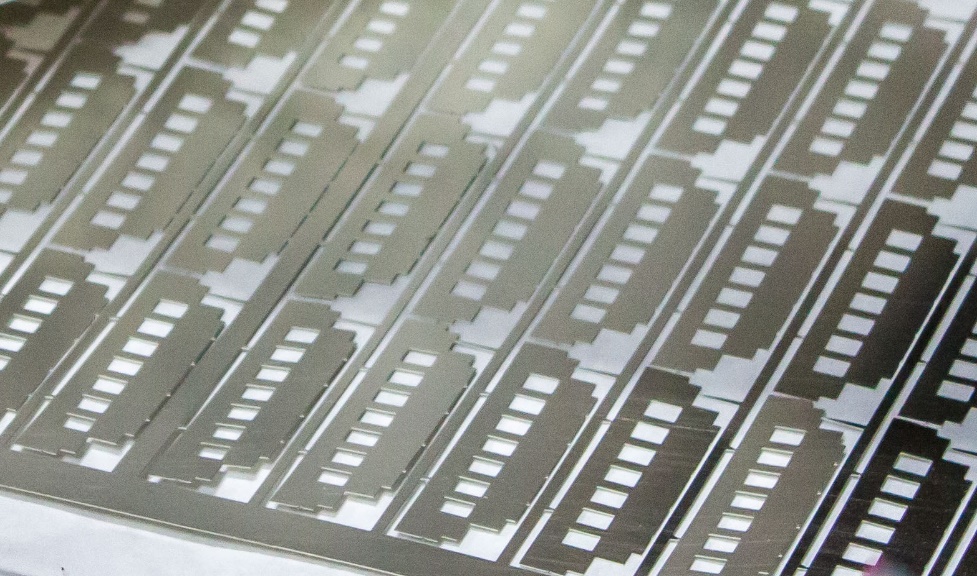

Miniaturization of complex, burr-free parts is, therefore, possible to produce within hours and designed to customers’ exact specifications.

Components and Metals Used

Lead frames, semiconductor cooling plates, EMI/RFI shielding, springs, connectors, and contacts can be produced with any size of a feature, so long as it is not smaller than the material thickness. Board-level shielding can be engineered to tight specifications.

We also offer chemical etching for metal shims or gaskets to match the exact specifications of your parts. In addition to burr- and distortion-free shims, our production team can produce high-quality precision battery springs and contacts, encoder disks, and other microelectronic components. A wide range of materials is also used, including:

- Aluminum alloys 1100, 1145, 3003, 5051, and 6061.

- Copper alloys 101, 102, and 110, as well as phosphor bronze, and brass, and nickel silver.

- Beryllium copper alloy 25/172.

- Nickel/nickel alloys 200, 201, 42, 48, and 49 as well as HyMu, Inconel 600, and Monel.

- Stainless steel alloys 301, 302, 304, 304L, 316, 316L, 321, 347, PH15-7Mo, and Type 17-7PH.

Stainless steel types 304L and 316L are suited for parts that require welding, while phosphor bronze is often preferred for springs. Nickel silver is suited for circuit board soldering and is a common material for EMI/RFI shielding.

Choose UWE for Photo Etched Electronic Components

United Western Enterprises Inc. provides photochemical etching for electronic parts per exact customer specifications. We can meet customer requirements—from prototyping to a full production order size. For stress-free customer service, to place a design order, or to request in-house forming services, including laser welding, and mechanical soldering as well as other value-added services such as heat treating, or plating, request a quote/information online or call (800)964-6461 today.