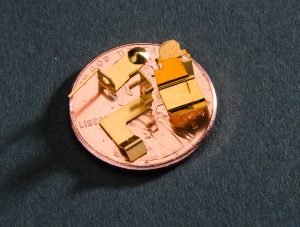

Custom Metal Forming Services for Photo Etched Parts

United Western Enterprises, with decades of unparalleled experience and expertise in precision parts manufacturing, is deeply committed to delivering comprehensive solutions that go beyond mere etching. Recognizing the diverse and intricate needs of your projects, we offer a suite of value-added options tailored to elevate the quality and precision of your components. Our advanced metal forming manufacturing processes, such as roll forming and press braking, are integral components of our broad service spectrum, promising you versatility and accuracy in every piece.

At United Western Enterprises, our in-house metal forming capabilities are fortified by our innovative tool-making proficiencies, ensuring each part is meticulously crafted to match your exact specifications. We take pride in our unwavering dedication to quality and precision, striving to fulfill your orders with the utmost speed and efficiency. This amalgamation of cutting-edge technology, skilled craftsmanship, and customer-centric service is designed to support your visions and projects seamlessly, delivering results that exceed expectations. Whether it’s a small-scale requirement or a large-scale industrial project, we are poised to meet your needs with our superior metal forming services, fostering reliability and excellence in every endeavor.

About Metal Forming

Metal forming is a common metalworking process that involves permanently deforming the material into the desired shape—known as plastic deformation—without adding or subtracting mass. Shaping metals in this manner can occur below the material’s recrystallization temperature (cold working) or above its recrystallization temperature (hot working).

There are several types of metal forming processes:

- Tensile forming – This process utilizes tensile stress to deform metal by expanding, stretching, or recessing the material.

- Compressive forming – This process involves utilizing compressive forces to deform raw metals. Techniques to achieve this include rolling, extrusion, forging, indenting, and die forming.

It’s also possible to use both tensile and compressive forming processes to shape metal parts. Spinning and deep drawing are two such methods.

- Bending – This process, often used with sheet metals, involves deforming metal around an axis.

- Shearing – This process utilizes shear spinning deformation to shape metals.

A wide range of tools is available to achieve these plastic deformation effects, from presses to dies.

Advantages of Metal Forming

Understanding the benefits of metal forming is crucial in selecting the optimal manufacturing process for your needs. Both hot and cold working processes present unique advantages and limitations that cater to specific requirements.

Hot forming is typically preferable when the project necessitates extensive deformations, due to the increased malleability provided by heating the metal. This method reduces yield strength, making the metal more accommodating to alterations. Nevertheless, this approach may necessitate subsequent treatments to alleviate the impacts of high temperatures, potentially adding to the cost.

On the other hand, cold forming is advantageous in producing stronger, more refined metal structures, and it omits the need for potentially costly heating treatments. The final products tend to have a smoother and more polished finish, which is often desirable. This technique is particularly efficient for projects that require enhanced strength and refined aesthetics without the additional procedural steps involved in hot working.

By comparing the intrinsic properties and outcomes of these techniques, we can better align the chosen method with the envisioned end result, ensuring that the material and structural integrity aligns perfectly with the intended application, and optimizing the balance between cost and performance. Balancing these aspects enables the creation of components that meet the stringent standards of quality and durability while maintaining economic viability.

Why UWE?

United Western Enterprises is an industry leader in metalworking, with extensive experience in handling a variety of materials. We will consult with you to determine which specific types of manufacturing processes are needed for your application, and then we will bring our wide-ranging skills to the task of providing you with the high-quality metal parts you need.

We are an AS 9100D / ISO 9001:2015 Certified Company. Our metalworking projects are carried out at our 21,000-square-foot building located in Camarillo, CA. Please contact us if you’d like more information about our metalworking processes. Request your free quote!