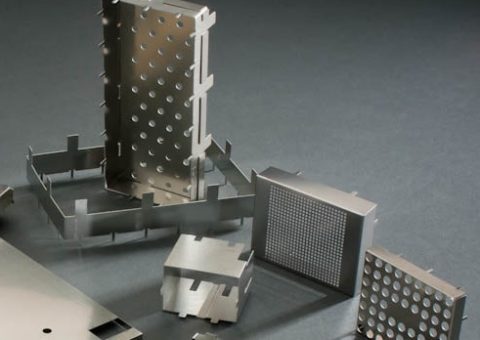

Photochemical Etched EMI Board Shielding

As mobile technology and consumer tastes evolve, the demand for thinner devices with higher data rates, larger operating frequencies, and multiple antennas is growing at paramount rates. This means that today’s new mobile devices require the best solutions for minimizing the effect of electromagnetic interference (EMI). The photo etching of EMI board level shields is one of many United Western Enterprise’s specialties. We produce one- and two-piece custom surface-mount shields to suit a variety of applications. Each shield is designed to eliminate crosstalk, or the transmission of signals from one circuit to another, which can create interference, equipment malfunctions, and damage. When it comes to the best company offering photo etching of EMI board level shielding, United Western Enterprises is known throughout the mobile device industry and others as the innovative leader in this unique space.

What is EMI Board Level Shielding?

Board level shields are etched two-piece and one-piece metal cages that help to offer the insolation of board-level parts, minimize potential EMI, reduce crosstalk, and achieve all of this without compromising the system’s speed and accuracy. EMI board level shielding by United Western Enterprises is engineered to meet any application requirement, regardless of the part shape and complexity. Thicknesses range is down to .0003” (although .005” to 0.20” is often suitable for board level shielding), so we can address the tightest tolerances. Cost and downtime are minimized, thanks to our ability to produce many parts at once, to a customer’s exact specifications, without the risk of damage and imperfections associated with other manufacturing methods.

EMI board level shielding by United Western Enterprises can be manufactured out of a wide range of metals that include brass, nickel, silver, beryllium, copper aluminum, nickel, and stainless steel alloys. If needed, parts can also be plated to improve integrity, solderability, and performance. Tin plating is often used, but we can apply nickel, silver, or gold plating if desired, and provide chemical film and anodizing services as well.

Why Should One Use EMI Board Level Shielding?

EMI board level shielding is a preferred option for a number of reasons that include lower costs, greater design flexibility, the ability to produce small EMI shields in any size, the ability to choose from a broad range of materials, and decreased tooling costs despite the complex geometries that are involved. In addition, EMI board level shielding allows our team to provide small holes and slots for heat dissipation, different mounting-pin configurations, part numbers, and logos.

Understanding the Difference Between EMI Board Level Shielding Types

When considering EMI board level shielding for your devices, it is important that you first understand the various types and options. Standard surface mount shields can be acquired in both two-piece and one-piece designs. Here are the differences: six sides of EMI protection are offered with one-piece shields with the board itself existing as the sixth side. This option offers economically-friendly shielding protection without the need for covered component access.

Two-piece EMI board level shielding comes with more flexibility than its one-piece counterpart. With EMI board level shielding in the two-piece format people have the flexibility to inspect and repair parts without running the risk of damaging the board by removing the entire shield, and it also helps to prevent the incurment of any tooling costs. Inspection and repair work is very easy due to the fact that the covers snap on and off, making the repair speedy and this reduces board re-work.

EMI Board Level Shielding Design Engineering

Before you reach out to our team of specialists at United Western Enterprises, you will want to determine the right type of EMI board level shielding that’s required for the application. After we are able to connect with your team and have a thorough understanding of your project and its specifications, United Western Enterprises will use the most advanced engineering systems to develop parts in mere days. In addition, most of our experts have 20 or more years of experience with advanced materials and application engineering.

Call United Western Enterprises for EMI Board Level Shielding Today

Whether you manufacture mobile phones, tablets, or your organization is in the aerospace, defence, or transportation industry, United Western Enterprises offers the best EMI board level shielding to accommodate your design needs and objectives. Give us today for a quote, and learn how our team of board level shielding engineers can help your organization cut costs while offering superior services and products.