What Is EMI Shielding?

Electromagnetic interference (EMI) is a disruption of signals between electronic components. It can interrupt the quality of a cell phone call, radio station, or signals passing through circuit boards. The solution is to surround electronic components and cables with EMI shielding. Metal screens, sheets, or mesh may be used to surround cables and other sensitive parts. These shields mostly resemble flat sheets that prevent electrical or magnetic fields from elsewhere interfering with the device, or from EMI interference being emitted by that device.

Where Does EMI Come From?

Sources of EMI come from man-made devices and the environment. Lightning, solar magnetic storms, and Earth’s magnetic field can generate interference, while computer circuits, as well as devices such as brush motors and arc welders, can generate their own interference. Power quality issues can cause EMI as well. A blackout, brownout, power line fault, voltage spike or sag, or electrical noise on a main power line can cause electromagnetic interference.

With cellphones in the hands of just about every citizen, overcrowded airwaves sometimes lead to disruptions of wireless signals. In short, wireless devices can interfere with one another. Other applications in which electronic devices may be affected by electromagnetic fields include:

- Medical equipment: Electromagnetic and radio frequency interference (RFI) can disrupt x-ray machines and patient telemetry equipment and-saving systems such as surgical room electronics, ventilators, and infusion pumps.

- Railroad/mass transit systems: Train control and propulsion systems, third rail shoes, and high-voltage contact switching systems may produce EMI that affects sensitive electronics. Signaling and control systems can as well, and they require shielding materials to function properly.

- Military assets/infrastructure: High-power microwave weapons, electromagnetic pulse cannons, and high-altitude nuclear electromagnetic pulse weapons—collectively assets of electronic warfare—can lead to the need to protect electronics even further from enemy activities.

What Are the Main Types of EMI Shielding?

EMI shields are found in many shapes and sizes and may be produced out of nickel silver, tin-plated steel, stainless steel, or Mu metal; they can also be brass, bare, or plated. In order to keep equipment in working condition and to comply with military and Federal Communications Commission regulations, the following types of electromagnetic shielding may be used:

Gaskets

Formed metal sheets can be produced in various sizes, shapes, and configurations to fit electronic enclosures. Metal screens used as EMI shields are now typically flexible to prevent deformation that can allow electronic circuits to leak and receive interference. Metal foams and wires may also be used; the most ideal type of shielding depends on the application. In some applications, a coating with a metallic ink can block EMI from exiting the interior of an enclosure.

Particle-Filled Silicones

To protect a ruggedized touchscreen, an EMI shield must be soft so not to interfere with the screen’s function while providing EMI protection, electrical conductivity, and environmental sealing. After all, silicones resist water entry, sunlight, and temperature fluctuations. Today’s nickel-graphite silicones perform as well as similar materials, yet are less expensive and meet the shielding requirements of the latest military specifications.

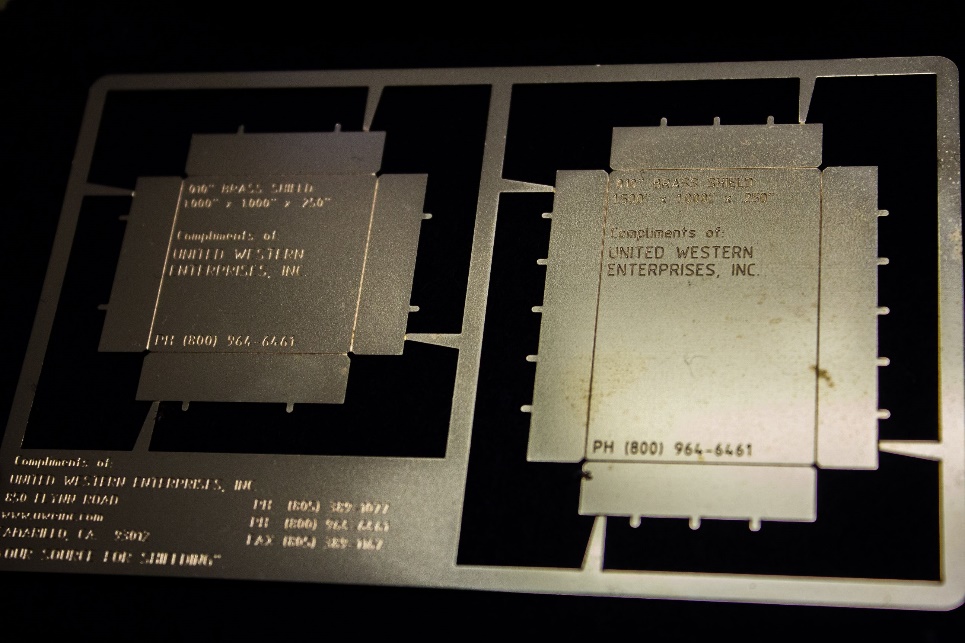

Board Level Shielding

Printed circuit boards, small and sensitive, are found in just about everything. One-and two-piece metal surface-mount shields, like the ones that can be custom made by United Western Enterprises, can easily isolate board level components and reduce electromagnetic interference.

How Electromagnetic Shielding Is Produced/Installed

Since gaskets and other shielding materials are often so small, cutting and stamping are not effective ways to make them. United Western Enterprises uses a chemical etching process that produces no stress on the material. Components can be designed to exact specifications, yielding parts that are thin, fit exactly into the application, and retain the material’s full strength.

We can provide forming services to ensure each part suits your electronic equipment. In-house welding and soldering services are also available. From power lines and cables to small grounded wires, to capacitors and other electronic components in circuits, the need to minimize EMI noise can be addressed with EMI shielding.

To learn more about our electromagnetic shielding parts, materials, and custom solutions, contact us online or by email or phone