Heat Treating Services for Precision Machined Parts

In the modern industrial sector, heat treating plays a vastly important role in fabricating metal parts for a broad range of applications. It may be fairly said that contemporary society could not exist in its present form without heat treating. This manufacturing process is used to fabricate a wide spectrum of parts—from fasteners to crankshafts—that are used in automobiles, computers, airplanes, and many types of equipment.

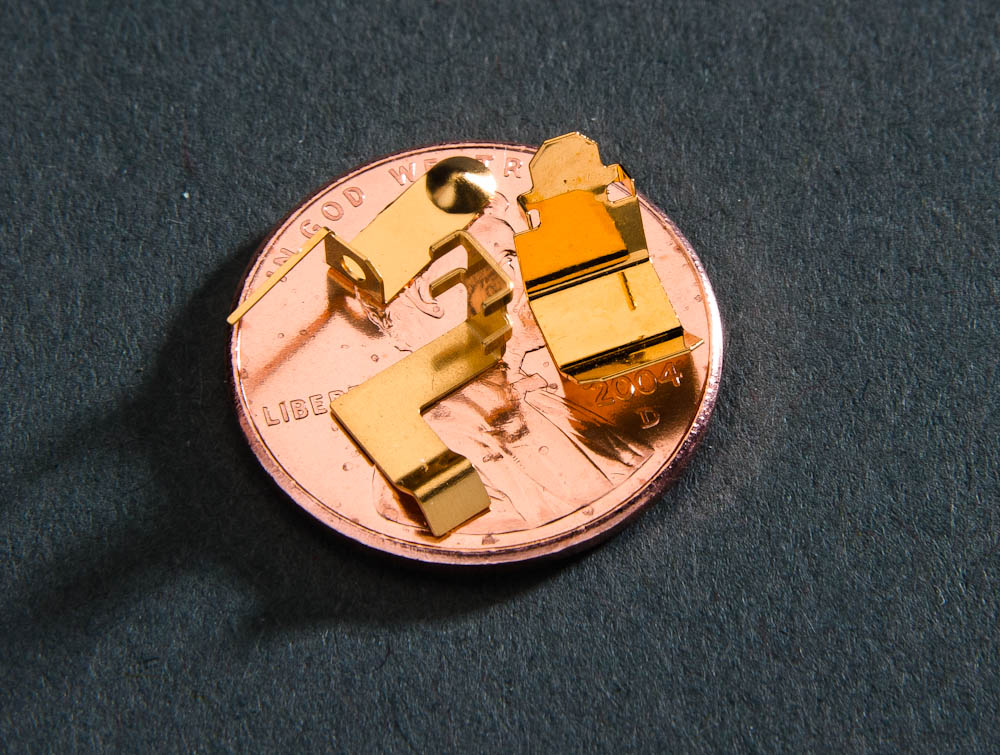

Heat treating steel and other materials is one of the value-added options offered by United Western Enterprises, Inc.

About Heat Treating

Heat treating is used to alter the mechanical properties of metals in conformity with manufacturing requirements. This is achieved by subjecting the metal to precisely controlled heating and cooling cycles.

First, the part is heated to a specific temperature, where it enters what is known as the austenite phase and its structure begins to alter. Then it is maintained at that temperature for a certain span of time, which can range anywhere from a few seconds to several days. After this, it is carefully cooled, quickly or slowly, depending on the effect the manufacturer wishes to create.

This process is commonly used in the fabrication of steel, but various metals and alloys can benefit from it as well, such as nickel, titanium, magnesium, aluminum, and beryllium copper.

Beryllium copper requires a two-step heat treating process: the material must first be heated and then subjected to age hardening to enable it to form precipitates. It can’t be heat treated from ½ hard to full hard with standard processes.

There are a number of heat treating processes used in the manufacturing sector. These include:

Carburizing – The process of enabling the surface of the material to absorb carbon, with the intention of making the part harder.

Quenching – The rapid cooling of a heating material, often with the use of oil, water, or an air furnace. This results in the hardening and strengthening of the material.

Case hardening – Also called surface hardening, this adds a protective layer to the material without altering the material deeper within. It is often used on gears, bearings, and other parts that are subject to contact fatigue. Carburization is one of the methods that can be used in case hardening.

Annealing – This process heats the material above its recrystallization temperature to enable the formation of new grains.

Decarburization – Basically the opposite of carburizing, this process reduces carbon content, which softens the material being treated.

Tempering – This process involves reheating the material below its critical point and then cooling it. The result is lower hardness and greater toughness.

Nitriding – This process adds nitrogen to the material, generally via plasma, gas, or a salt bath, in a manner similar to carburizing steel. It is sometimes used in case hardening.

Vacuum hardening – This process heats the material in an oxygen-free environment. Advantages of vacuum hardening include increased hardness without decarburization.

Advantages of Heat Treating

Heat treating can alter the composition and performance qualities of metal in many ways. Production benefits of heat treating include but are not limited to:

- Increase or decrease in material hardness

- Increase or decrease in electromagnetic properties of ferrous metals

- Improved machinability

- Enhanced tensile strength

- Corrosion resistance

Why Choose United Western Enterprises?

With decades of experience in the heat treatment of steel and other materials, United Western Enterprises is the partner you need to ensure that your parts are ready for the marketplace. Our customers hail from many different industries, from the aerospace sector to the medical field. A free consultation is available. If you have questions about our heat treating processes, feel free to call us at 800-964-6461. You may also request a quote online.