Why Photo Etching is Cost-Effective

Photo etching enables metal parts to be produced with precision, speed, and affordability. The chemical etching process is just right when it comes to efficiently and economically creating burr-free, precision parts.

Why Use Photo Etching?

Chemical etching is an efficient and cost-saving way to fabricate metal parts. The process takes things a step further than early acid etching techniques, by using computer-aided-design (CAD) software, modern etchants, and photoresist systems to produce complex parts out of metals.

Many factors play into why photo etching can be more cost-effective than other production techniques. For one, the process is extremely precise; UWE can work with materials down to .0003” thick with holes as small as .004”, at extremely tight tolerances (for edge dimensions, a tolerance of +/-10% of the material thickness is possible).1

Cost-saving aspects of chemical etching include:

- Design complexity

- Process time/speed

- Tooling

- Quality

- Mass production

- Accurate results

How these factors help lower production costs will be discussed later. First, here is an overview of how photo etching works.

How Does Metal Etching Work?

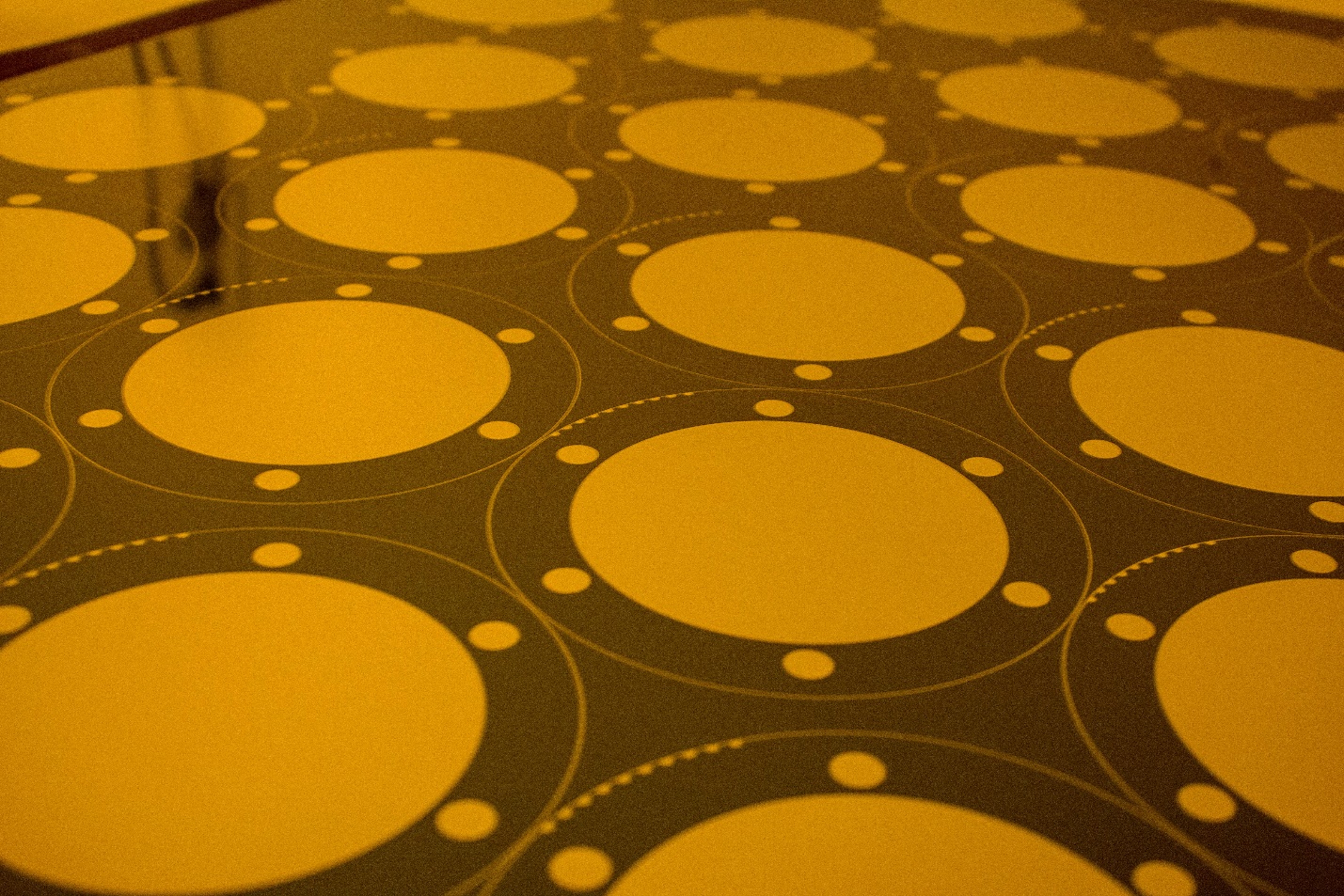

The chemical etching process is a form of subtractive manufacturing. Also known as photo chemical etching, it requires a CAD drawing from which a photo tool is created (the photo tool is essentially a template for the final product). Digital CAD files can be mailed to an etching company or submitted with an email.

Next, the metal to be used is selected, which can be stainless steel or a copper, aluminum, or nickel alloy. The sheet is covered on both sides with a film-like photoresist coating, designed according to the customer’s files. It is then exposed to ultraviolet (UV) light.

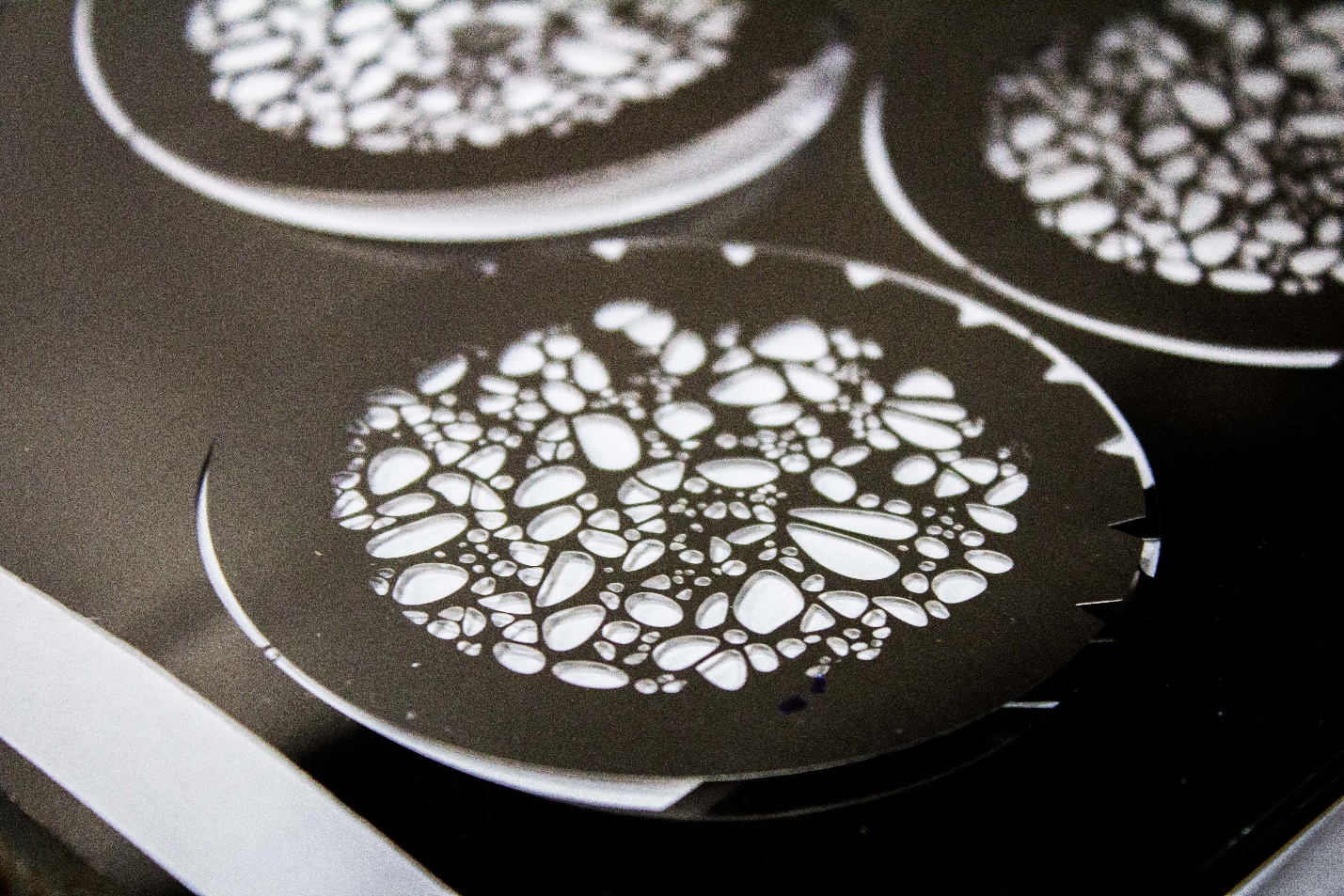

The printed design on the photoresist polymerizes and hardens when exposed to UV light, protecting the underlying metal. Unexposed areas are washed away during the development process, and an acid etchant is sprayed onto the metal to dissolve unprotected metal surfaces. The remaining polymerized photoresist is washed off with an alkaline solution, yielding a finished part or chemical engraving of logos, letters, numbers, and other details.

Machining processes can be further refined to create multidimensional components or score lines that allow parts to be folded. The entire production process is explained in greater detail by R&D Magazine. Additional value-added services such as heat treating, laser welding, and plating can be performed; UWE offers these services to meet customers’ exact specifications.

How Chemical Etching Cuts Costs

Chemical etching enables complex parts to be produced quickly and affordably. Other manufacturing techniques can only produce one part at a time, but chemical etching allows many parts and components with different geometries to be formed together on a single metal sheet. Versatility is one of the greatest cost-saving advantages, but there are more, which include:

1. Design Complexity

Design complexity generally doesn’t equal higher chemical etching costs. Therefore, high-precision metal parts can be designed with intricate features and produced within budget and on time. Engineers can be more creative with circuit components such as thin screens, meshes, gaskets, seals, heat sinks, springs, electrical contacts, and EMI/RFI shields.

2. Processing Time/Speed

Lead time is reduced because many parts can be etched simultaneously. Phototools may be produced in less than 24 hours, allowing some parts to be completed within a day. Part thickness is the primary factor affecting etching time. With UWE’s process, an etch rate of 0.0005 to 0.001 inches per minute (per side) can be achieved.2 Thermal stress is also not a factor, so customers receive components that meet their expectations—no rework is needed, so only the costs of the initial process need to be considered.

3. Tooling

An etching tool can be produced within hours. Designing it can be compared to creating a film. On the other hand, it can take weeks to build a stamping die. Tooling costs alone can run into the thousands of dollars. Chemical etching tools cost far less. Also, wear and tear and maintenance don’t factor in; whereas other manufacturing tools are often designed for a single process or production run.

4. Quality

High-precision parts are produced burr-free and without thermal damage. Chemical etching dissolves metal uniformly and evenly until the finished product is completed as designed. Burrs or other imperfections do not form during the etching process, eliminating the need for edge work or other finishing steps. Deburring, which can be a time-consuming and costly step, is completely avoided.

5. Mass Production

Stamping and punching often will require a production volume that justifies the expense of creating the tooling for the components. Chemical etching enables many parts to be created at an affordable price. Mass production of intricate parts such as semiconductor lead frames can be attained, which can be too fragile to be made otherwise. Up to millions of pieces can be made economically and, the more parts per sheet, the lower the unit labor cost. Customers can, therefore, cost-effectively choose alloys, such as Nickel Silver, for RF shielding soldered onto printed circuit boards.

6. Turnaround

As stated earlier, creating a photo tool can take just a few hours. Completing a part or shipment may require just a few days—from the initial order to delivery. Customers can get a prototype completed or a product to market faster, which saves on production costs and enables a company to start profiting from its bottom line. Also, when order changes are made, adapting tools and processes does not significantly increase lead time. These adjustments are less costly to implement as well.

Conclusion: Photo Chemical Etching vs. Laser Cutting or Stamping

The most cost-friendly process depends on your production requirements. However, the chemical etching process has the best cost advantages when design complexity, process speed, tooling, product quality, and high-volume production are considered. Aluminum, stainless steel, and copper etching are highly accurate and eliminate other costly steps such as deburring.

As accurate and precise as it is, chemical etching also cuts the costs of redoing work, wasting materials as a result, and ordering additional production runs to get things right. Whether you require a small or a large order, United Western Enterprises has an in-house forming department that can quickly produce common or custom-ordered precision metal parts.

To learn more about how our advanced chemical etching techniques can help your business, call (800)964-6461 today or email sales@uweinc.com. Also, visit our contact us page to obtain more information or request a quote or call from our team.

Sources:

1. https://www.uweinc.com/dimensions-and-tolerances/

2. https://www.uweinc.com/photo-etching/advantages-photo-chemical-etching/