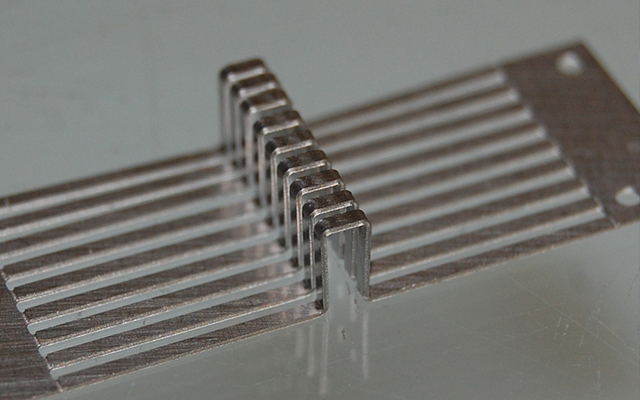

Stainless Steel Photo & Chemical Etching Solutions

Supplying many types of etched metal products to different industries, United Western Enterprises specializes in chemical etching of stainless steel. We can produce high-quality components in any quantity. Complex prototypes and volume production parts are produced without hard tooling and the expenses associated with other processes. Chemical etching also results in faster lead times, even for complex, high-volume orders.

Stainless Steel Alloys

We can apply photochemical etching to a wide range of stainless steel alloys, including:

Type 301, like all 300 series stainless steel, is work-hardened to achieve higher tempers.301 is good for such applications as springs, clamps and brackets.

Types 302/304 are general-purpose stainless steel alloys. They are somewhat more corrosive resistant than 301. They can also be cold-worked to higher tensile strengths, although they become less ductile compared to type 301.

Type 304L is similar to type 304 but has less carbon, making it a good choice for parts requiring welding.

Type 316 is often used for food and medical applications.

Type 316L, like 304L, has lower carbon content than 316, which makes it a good choice for parts requiring welding.

Type 321 and 347 offer the advantage of excellent resistance to intergranular corrosion at temperatures in the range of 800 degrees F to 1500 degrees F or at lower temperatures after holding in this range.

PH15-7Mo is a commonly used precipitation-hardening stainless steel that has good work-ability, high strength, and fair corrosion resistance. It also has great mechanical properties at high temperatures. Molybdenum content provides more strength than other PH grades, with similar hardening treatments.

Type 17-7PH can be etched in either the annealed condition or in a work-hardened temper. Both tempers can later be heat-treated for increased strength.

What Is Stainless Steel Etching?

Etching steel involves anything from creating lines and grooves to fabricating precision metal parts with dimensions that account for tight tolerance requirements. Photochemical machining requires a photo-resist coating to be created, which serves as the primary design tool. Material that’s exposed to ferric chloride, hydrochloric acid, and other substances dissolve to create the finished part.

About Stainless Steel and Acid Etching Metal

Acid etching of stainless steel enables clients to benefit from the corrosion-resistant properties of this material. Stainless steel can be milled into any shape or thickness (we can etch materials down to .0003 inches) and can be produced in any custom design or pattern. It is also highly durable, requires little maintenance, and can be recycled. Photo etching of stainless steel is a preferred process for applications such as:

- Medical devices/components

- Fuel cell plates

- RFI/EMI shielding

- Optical apertures

- Encoder disks

- Battery springs/contacts

- Covers and lids

- Micro-electronics

- Military/aerospace electronics

These are just a few examples of stainless steel items that can be produced using the etching process. We also specialize in chemical etching steel to produce a variety of custom metal parts with fine thicknesses, small holes, and a high degree of flatness.

Chemical Etching of Stainless Steel vs. Other Processes

Photo chemical machining is an efficient process, as chemicals can etch metal faster than acids. Hydrochloric acid may be used, but it can cause pitting in stainless steel. Nitric acid mixed in a suitable ratio can work for acid etching metal. During the manufacturing process, no mechanical stress is introduced to the part, as it is with stamping, punching, or die cutting. This avoids burring, deformation, or heat damage that can require additional manufacturing steps or rework.

Many production processes limit how many parts can be produced at once. Creating stamping tools, alone, can take weeks and add thousands of dollars to a project. Expensive tooling also tends to wear out, requires maintenance, and needs replacement over time. This is not the case with chemical etching. Production and even design changes associated with chemical etching stainless steel also known as acid etching steel are often a fraction the cost compared to laser cutting or Electrical Discharge Machining.

Photo Etching Stainless Steel Parts is United Western Enterprise’s Specialty

Our photo etching process allows for etching steel in a wide variety of applications. We handle the entire process, from CAD and photo tool design, to applying the photoresist coating to the metal sheet, exposing it to UV light, and matching etchants with the base material. Using their extensive knowledge, our technicians can pick the most effective chemical machining process and ensure parts meet high standards for quality.

To inquire about chemical etching of stainless steel and/or request value-added services such as soldering, laser welding, or plating, contact us on the web or call (800)964-6461.