How Photochemical Etching Is the Answer to New Automotive Innovations

As any car enthusiast will tell you, automobiles aren’t what they used to be. Road vehicles have gone through a lot of alterations, inside and out, that make the automobiles of today very different from those of generations past, both in their appearance and in their driving capabilities.

It’s clear, too, that the automotive industry is still rapidly evolving, with many more innovations right around the corner. Some of these future advancements, like self-driving cars, have received plenty of press, but others are largely unnoticed, or at least underappreciated, by the general public. Among these under-the-radar developments is the trend toward miniaturization.

Smaller Is Better, But …

It’s certainly no big secret that today’s cars are smaller and more lightweight than their forefathers, but automotive miniaturization goes further than many people realize. Many car components have been miniaturized. A big catalyst behind this phenomenon is the increasing popularity of eco-friendly hybrid and electric vehicles, which are expected to dominate the roads of the future. These types of automobiles require lighter parts than vehicles with standard gasoline engines.

However, all this poses a serious problem for automotive manufacturers: How can you miniaturize essential components without sacrificing durability or reliability? Photochemical etching provides the solution.

When it comes to creating high-quality miniature parts and components, photochemical etching (also called photochemical milling and photochemical machining) cannot be equaled for its flexibility and range of benefits. As a leader in the field, United Western Enterprises provides a wide range of photo-etched parts for the automotive industry. Let’s take this opportunity to survey the many advantages of photochemical etching.

Specific Benefits of Photochemical Etching in Auto Engineering

The manufacturing process known as photochemical etching combines computer-aided design (CAD), chemistry, photography, and metallurgy to produce close tolerance precision metal parts. Though it is a powerfully effective process, it is not the only one available. Stamping and lasering, for example, are two competing ways to manufacture innovative auto solutions that incorporate precision metal parts.

This brings up an obvious question: Why photochemical etching? Why has it become the generally preferred option for crafting innovative auto parts? There is a variety of reasons why photochemical milling is usually—not always, but usually—the best option for advanced metal etching.

Cost-Effectiveness

Lasering automotive parts can create products with the same level of precision as photochemical etching, but lasering is also significantly more expensive than chemical milling, which can be a costly problem for large production runs. Photochemical etching gets the job done at considerably less expense.

No Tooling Investment

With standard machining techniques, modifying an existing design or creating a prototype requires creating a brand-new tool for the job. This takes time and money, both of which tend to be in short supply. With chemical etching, there’s no need for this. It’s possible to create small runs of a product without any of the burdens involved with creating specialized tooling for the purpose. A small nonrecurring engineering cost is all it takes.

Rapid Prototyping

Dispensing with the need for specialized tooling also enables manufacturers to create prototypes with relative ease.

High Accuracy

Standard mechanical etching is often inadequate or impractical for extremely complex, elaborate parts. Often, it’s impossible to ensure exact reproducibility. Photochemical milling uses computer-aided design to create extremely precise features that stamping and similar processes cannot replicate.

Will Not Harm Delicate Materials

Standard machining processes can harm thin, fragile parts. That’s an especially tricky issue in our age of auto engineering miniaturization. Milling processes that involve heat or presswork are often untenable for extremely tiny components. For example, springs can easily undergo deformations that hinder their recoil properties. By contrast, photochemical etching is a stress-free process that will not alter the properties of the material, no matter how tiny or delicate it may be.

Burr-Free Manufacturing

Laser etching often creates burrs and rough edges, which is a significant hindrance for miniature parts that require ultra-smooth contours. Photochemical milling avoids this complication, leaving behind no superfluous material and causing no damage to the part.

Wide-Ranging Applications

Photochemical etching can be successfully used on nearly any type of metal—steel, copper, nickel, aluminum, titanium, and much more—making this a go-to option no matter what kind of material you’re working with. From long, bulky parts to extremely thin materials (as little as 0.0003″ thick), a very broad spectrum of metals can be subjected to the milling process.

In sum, photochemical etching is usually the most cost-effective and efficient way to create precisely crafted, innovative auto solutions and parts.

Automotive Components Created by Photochemical Etching

As we have noted, photochemical milling can be used to create a wide array of parts. In the auto industry, this process has been—and continues to be—used to manufacture the following components:

| Spring connectors | Fuel cell features (frames, screens, end caps) |

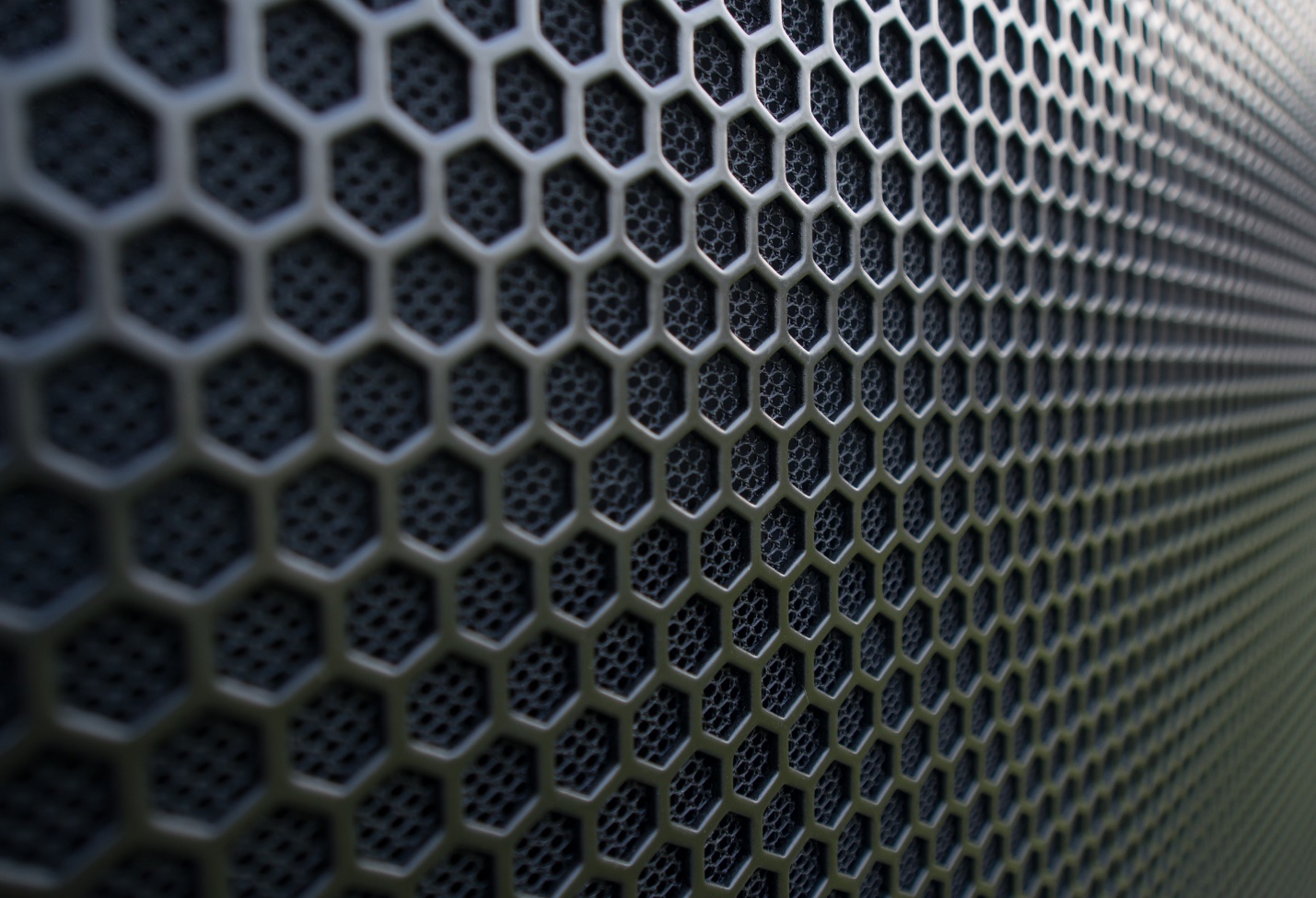

| Gaskets | Speaker grilles |

| Contacts | Lead frames |

| Electrical contacts | Shock absorber washers |

| Fuel injection filters | Oil control valve filters |

| Diffusers | Fluid system screens |

| Heat exchanger plates | EMI & RF shielding |

| High-tension springs | Optical encoders |

| Damper shims | GDI flexures |

| ABS flexures | Various meshes |

As auto engineering continues to rely on miniaturization, it is expected that the range of parts created by this process will gradually expand.

Contact United Western Enterprises for Automotive Photo-Etching Services

In operation since 1969, United Western Enterprises Inc. (uweinc.com) provides high-quality photo-etched parts to multiple industries, including the automotive sector. Aside from our photoetching services, we offer in-house laser welding, heat treating, and plating services as well. For additional information about our etching services, please feel free to call us at (800)964-6461 or contact us on our web form. You may also request a quote online.