Photo Etching for the Aerospace & Military Defense Industry

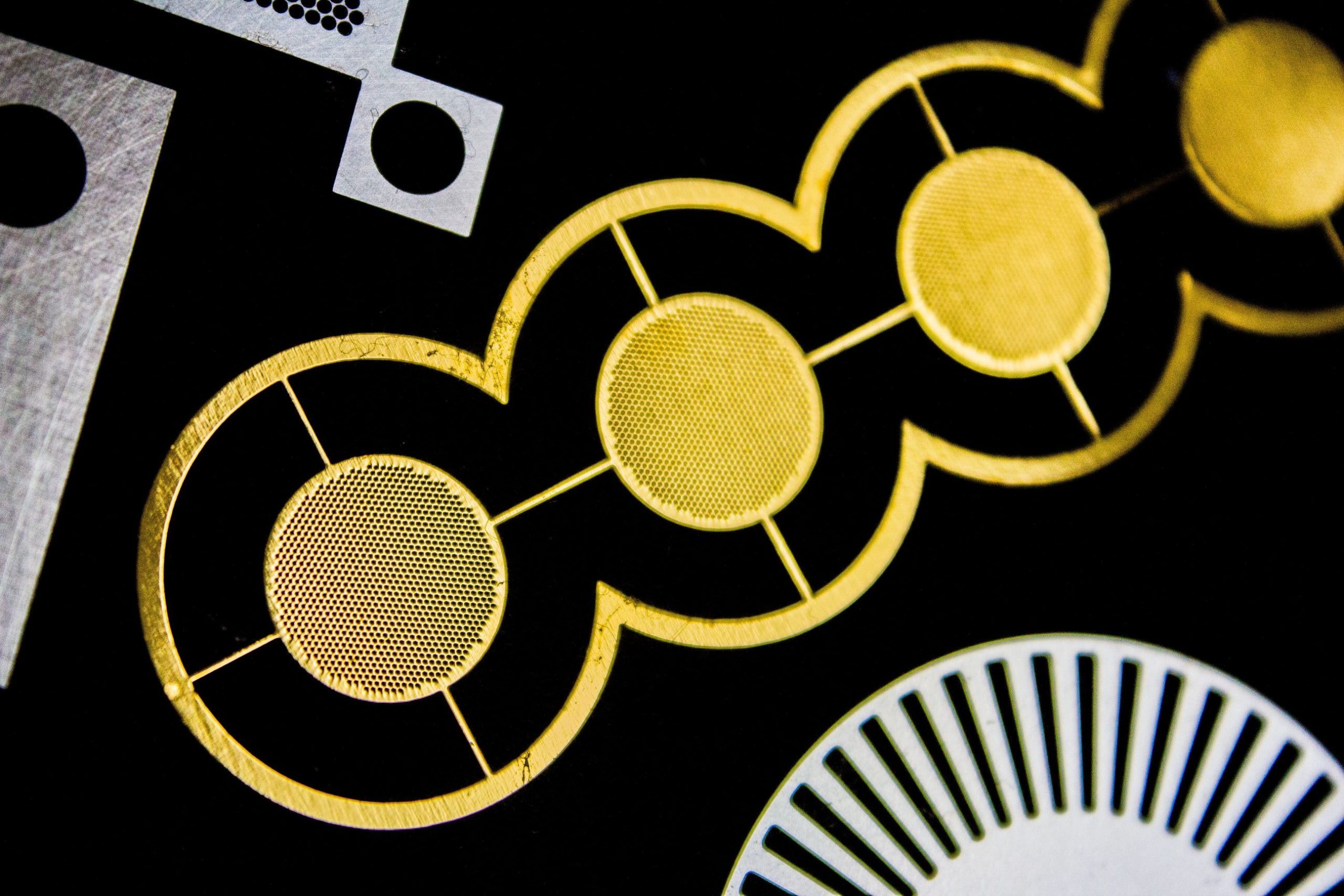

United Western Enterprises Inc. is an AS 9100D and ISO 9001:2015 certified photochemical etching company that specializes in photo etching for the aerospace industry and defense contractors. Our etching capabilities yield high precision, tight tolerance parts that can be used in airplanes, satellites, and weapons systems. Thanks to technological improvements and our commitment to customer service, we can produce materials on the order of ten-thousands-of-an-inch thick.

In fact, we can etch a material as thin as .0003” up to .064” thick, with holes as small as .004”. However, we can work with even thicker materials if a customer requires engraving. Our equipment can engrave characters into materials up to .250” thick. A tolerance of ±10% of material thickness is possible as well. All this comes with a quick turnaround time to accommodate a customer’s scheduling requirements.

All in the Details

Photo etching for military defense and aerospace companies enables us to create precision metal parts used in aircraft, weapons, and other sophisticated machinery. In applications from prototyping to full-scale production of any order size, we can focus on:

- Quality: We can use aerospace grade materials, including aluminum and titanium. During our machining process, we use non-contact methods that eliminate heat stress and distortion. Completed parts are burr-free and ready for bonding, stacking, or actuation, while costly rework is avoided thanks to our stress-free process.

- Miniaturization: Parts and machines, including drones, are becoming increasingly smaller. That often makes riveting, welding, and punching impractical, but we can bond laminations using the photo-resist. The metal surfaces are, therefore, protected throughout the etching process. We can etch parts with small dimensions to meet very precise requirements of customers.

- Part Complexity: Highly complex parts can be produced with no increase in cost or production time. From part geometry to tiny channels, every dimension of a part is etched simultaneously, regardless of complexity. Then again, producing a part as basic as a washer is fast and easy. Chemical etching for passenger jet parts is possible with tolerances acceptable within industry safety regulations.

Components and Metals Used

Titanium, aluminum, and other metals often used in aerospace and military applications can be photo etched. We use a range of alloys to accommodate customers’ design parameters, including nickel, stainless steel, and beryllium copper. For customers who demand 316L stainless steel, we can even provide welding services. Welding is available as part of our in-house forming services, along with heat treating and plating.

The range of components we can produce include:

- EMI/RFI shielding

- Apertures and other optical parts

- Battery springs

- Electrical contacts

- Encoder disks

- Covers and lids

- Fine metal screens

- Lead frames

- Heat sinks

- Wire mesh

- Stabilization shims

- Custom thin metal parts

Choosing a Photo Etching Specialist

We can produce common aerospace and military components such as filters, electrical interconnects, board level shielding, fuel cell parts, flat springs, and targeting/positioning components. United Western Enterprises Inc. has served the aerospace industry since 1969, providing common and customized parts for customers. Contact us today for information or to request a quote, or call us at (800) 964-6461.