Copper Alloys

Copper is one of the most commonly machined metals, and copper etching is important for many types of projects. A soft metal, copper is well suited for chemical etching in electrical and electronics manufacturing. It is second only to silver in terms of electrical and thermal conductivity.

What Is Copper?

Copper is an abundant metal and is malleable, ductile, and recyclable. Photo etching of copper can yield many types of products, from sheets and plates to strips, rods, and tubes. It is often preferred for its machinability and resistance to corrosion when properly coated or plated. The ductility of copper enables it to be stretched to long lengths, which is useful for applications such as wire or tubing.

Thanks to its malleability, copper can be flattened to nearly any thickness. It doesn’t require special preparation for soldering. The metal also maintains its texture when exposed to a copper etching chemical solution, while its color is not easily distorted.

Copper Alloys

Copper typically comes in three major alloys:

- Copper 101 is 99.99% pure copper.

- Copper 102 is 99.95% pure copper.

- Copper 110 is 99% pure copper.

Other alloys include the following:

- Brass

- Beryllium Copper. More than 90% copper with beryllium added. This material will have good conductivity and can be heat treated after forming to instill it with very good spring characteristics.

- Phosphor Bronze. Stronger than pure copper; used in spring applications.

- Nickel Silver. Despite the name, “Nickel Silver”—also referred to as “German Silver”—has no silver in its alloy. It is a nickel/copper alloy that has the luster of nickel plating but without the cost. It has good solder-ability and is often used for RF shielding that needs to be soldered onto a circuit board.

The advantages of copper alloys are many: They generally provide a high degree of strength, durability, thermal/electrical conductivity, malleability, and corrosion resistance. Highly skilled in the chemical etching of copper, United Western Enterprises frequently works with a broad range of alloys.

Where Etched Copper Is Used

Chemical machining is used on copper parts in a variety of industries, including the automotive, electronics, mining, medical, and aerospace sectors. Etched copper can also be found in printed circuit boards and any PCB component that’s part of an electrical circuit, including:

- Contacts, pins, connectors, and terminals

- EMI/RFI shielding

- Lead frames

- Formed metal enclosures

- Enclosures with snap-on lids

In addition, etched copper is an important component in UHF/microwave antennas and waveguides, as well as fuse links and bus bars. It is used for intaglio prints and injection molding inserts as well.

Benefits of Copper Etching

Chemical machining is preferred for copper and other metal parts because they’re not easily damaged in the process. The procedure involves the use of a copper (CU) etching solution, such as ferric chloride, rather than thermal or mechanical force.

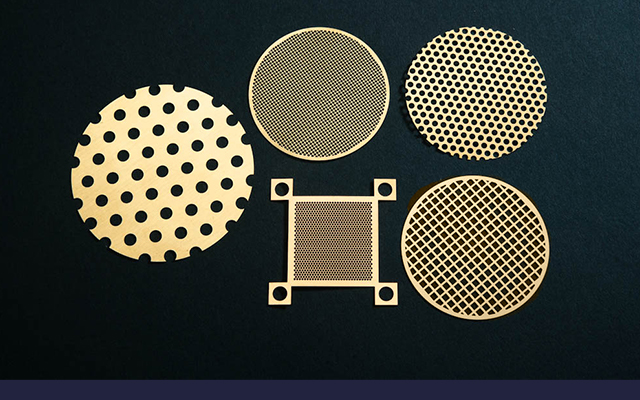

With copper etchants, there is no heat distortion and no burrs are left behind that require additional processing to remove imperfections. The copper etching process can be controlled to create features with varying thicknesses. Surfaces can be marked with part numbers or logos, or perforated to allow bending and shaping later in the fabrication and assembly process. Micro etching, especially on beryllium copper, can improve bonding later.

Photochemical Etching vs. Other Processes

Chemical etching isn’t the only way to create custom copper alloy parts and components. Alternative processes include laser cutting, metal stamping, EDM, and water jetting. Nonetheless, chemical etching is frequently the best option available for copper plates and similar materials. Here are a few ways in which photochemical etching copper parts tends to be superior to competing options:

- The process of etching the plate chemically places no mechanical pressure that can cause warping. This sets it apart from processes such as metal stamping, which is often unsuitable for fine or delicate materials.

- Photochemical etching does not produce thermal stress that can distort materials, while laser cutting often results in burrs on the surface of the plate.

- The copper etching process treats the entire part all at once, excluding the protected areas covered with a thin layer of acid resist. Even highly complicated designs and large production runs can be completed quickly. This results in a relatively high etch rate. By contrast, processes such as water jetting and laser cutting work in sequential fashion. That’s why these processes usually take significantly longer.

- Copper etching does not require the kinds of expensive tooling associated with CNC machining and metal stamping. Etching involves the use of chemicals and CAD software, which are relatively simple, and inexpensive, to maintain. The result is lower production costs.

In many cases, photochemical etching is just the all-around best solution for the treatment of your copper materials.

Industries Served

Etched copper components are frequently utilized in many types of industrial applications. These industries include:

- Construction

- Automotive

- Medical

- Aerospace

- Electronics

- Consumer products

- Transportation

- Mining

Having honed our skills over many years of experience meeting the production needs of various industries, the team at UWE, Inc., can bring their chemical etching expertise to bear on even the most demanding applications involving copper and copper alloys.

Pick United Western Enterprises, Inc., for Copper Photo Etching

An AS 9100D- and ISO 9001:2015-certified company, we are photo chemical etching specialists and experienced with producing precision parts via copper etching. Our capabilities include etching shielding, covers, lids, printed circuit components, and other metal parts. We are well versed in handling a range of alloys, including brass and bronze, in the chemical etching of copper. To learn more, discuss your application, or request a quote, contact us on the web or call (866) 579-1719.