The Impact of Photo Chemical Etching on the Electronics, Aerospace, and Automotive Industries

October 2023

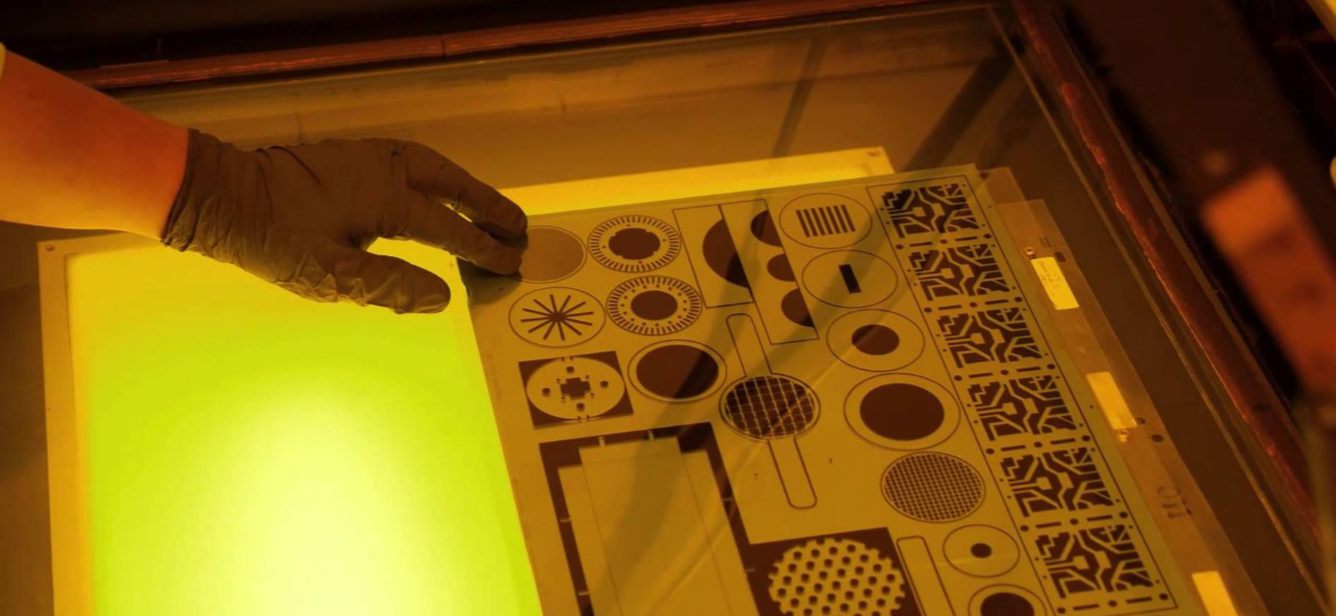

There is no doubt that modern manufacturing has been transformed by the advent of photo chemical etching. Its influence extends across various manufacturing sectors, but it has been particularly transformative in the worlds of electronics, aerospace, and automotive industries. Each of these fields, driven by demands for innovation, precision, and efficiency, has found an ally in photo chemical etching.

Below, we’ll explore the remarkable journey of photo chemical etching in these three industries. We’ll delve into how photo etching has not just adapted to the unique challenges of each industry but has also propelled it into a new era of technological advancement.

Photo Chemical Etching in the Electronics Industry

The electronics industry, a domain where innovation and miniaturization are not just goals but necessities, has been profoundly transformed by photo chemical etching. This process has reshaped how electronic components are designed and produced, catering to the industry’s relentless pursuit of smaller, more complex, and highly efficient devices.

The Demand for Precision and Miniaturization

In an era dominated by smartphones, wearables, and IoT devices, the electronics industry faces the ongoing challenge of producing smaller yet more powerful components. Traditional manufacturing methods often reach their limits when it comes to the level of detail and accuracy required for today’s microelectronics.

Photo chemical etching is a powerful solution to this problem. It allows for the production of components with exceptionally fine features, meeting the critical tolerances necessary for advanced electronic devices. This process supports the trend towards miniaturization, as it enables the creation of components that are not just smaller but also more complex in design—all without compromising their functionality.

Unleashing Design and Innovation

Photo chemical etching excels in its ability to prototype designs rapidly. This is very important in an industry where the lifecycle of a product is so dynamic. Engineers and designers can quickly move from concept to prototype to production, experimenting with different designs and functionalities without the constraints of traditional manufacturing methods. This flexibility significantly reduces time-to-market for new products and allows for greater innovation in component design.

Advantages in Manufacturing

The manufacturing benefits of photo chemical etching in electronics are many. Firstly, it ensures a high degree of material utilization, minimizing waste—a significant factor considering the precious metals often used in electronic components. Secondly, it’s a process that avoids heat-induced distortion that can harm delicate electronic parts. Finally, the lack of physical contact during the etching process means there’s no mechanical stress placed on the material, so its original properties and functionality are preserved.

Photo chemical etching allows the electronics sector to keep pace with the ever-growing demands for miniaturization and complexity. As the industry continues to evolve, photo etching can help turn what was once considered impossible into a manufacturable reality.

Photo Chemical Etching in the Aerospace Industry

In the aerospace industry, where the margin for error is virtually nonexistent, photo chemical etching has introduced a new era of manufacturing excellence. This technology has been instrumental in producing a range of components, from shims to encoder discs, that not only meet but exceed the rigorous standards of safety and performance required in aerospace.

Meeting High Precision and Safety Standards

Components used in aircraft and spacecraft must withstand extreme conditions, from intense pressures and temperatures to the rigors of space travel. Photo chemical etching rises to these challenges by providing a manufacturing process capable of producing parts with exceptional precision and consistency. The process allows for the creation of strong, lightweight components with a level of detail that traditional methods struggle to achieve. This precision is vital in aerospace applications, where every micron matters.

Innovations in Lightweight and Durable Components

Weight reduction without compromising strength or integrity is a key goal in aerospace design. Photo chemical etching contributes significantly in this area by enabling the manufacture of parts that are not only lighter but also maintain structural integrity. This weight optimization plays a huge role in improving fuel efficiency and overall performance of aerospace vehicles.

Cost-Effectiveness and Production Speed

In an industry where cost management is as critical as technological advancement, photo chemical etching offers an economically advantageous solution. Unlike traditional manufacturing processes, photo etching requires no expensive tooling, and it also facilitates rapid prototyping. This is particularly beneficial in an industry where development cycles can be lengthy and costly. The efficiency of photo chemical etching means that aerospace manufacturers can produce high-quality components more quickly and at a lower cost.

By enabling the production of parts that meet the industry’s stringent requirements for precision, durability, and lightweight design, photo chemical etching has opened new possibilities for innovation in aerospace engineering. This technology paves the way for future advancements in aerospace design and construction.

Photo Chemical Etching in the Automotive Industry

The automotive industry has been significantly impacted by the advent of photo chemical etching. This manufacturing technology has brought about a revolution in how automotive components are produced, aligning with the industry’s shift towards more sophisticated, reliable, and environmentally friendly vehicles.

Addressing Automotive Industry Demands

The modern automotive industry is marked by a relentless drive towards producing vehicles that are safer and more efficient, as well as aesthetically appealing. This objective calls for components that are both precisely engineered and highly reliable; these include heat shields, gaskets, spring contacts, filters, and many other parts.

Photo chemical etching provides an enormous benefit with its ability to produce complex, lightweight parts. The process is especially valuable in developing components for new-generation vehicles, including electric and hybrid models, where weight reduction and component reliability are vitally important.

Enhancing Design Flexibility and Customization

Photo chemical etching offers the automotive industry an unmatched level of design flexibility. This process allows for the rapid prototyping and production of intricate designs that would be challenging or even impossible to achieve with traditional manufacturing methods. The ability to quickly adapt and modify designs without incurring significant costs or delays allows manufacturers to respond swiftly to emerging market trends.

Improving Manufacturing Efficiency

Photo chemical etching is not just faster than many conventional manufacturing methods—it’s also more cost-effective, particularly when it comes to producing small to medium-sized runs of specialized parts. This efficiency is important in an industry where the pressure to reduce costs without compromising quality is ever-present. Additionally, the process’s precision minimizes material wastage, which complements the industry’s growing focus on sustainable manufacturing practices.

The impact of photo chemical etching in the automotive industry extends beyond current applications. As vehicle technology evolves, particularly with the rise of electric vehicles and advanced driver-assistance systems, the demand for highly specialized and precision-engineered components is expected to skyrocket. Photo etching is poised to play a critical role in meeting these demands.

Contact UWE

With years of dedicated service and a deep understanding of photo chemical etching, UWE is well positioned to help bring your innovative designs to life. Whether it’s advancing the frontier in electronics, pushing the boundaries in aerospace, or driving forward the latest in automotive technology, our team is ready to collaborate with you.

We invite you to reach out to United Western Enterprises for your next photo etching project, where our commitment to excellence and innovation will help turn your visionary concepts into reality. Contact us at (800) 964-6461 with your specs or questions.