What is EMI Shielding and Why Is It Critical for the Design of Your Electronics?

July 2022

EMI shielding, short for electromagnetic interference, is incorporated during the manufacturing process of electronic equipment such as mobile phones, tablets and radios that prevents the disruption of signals between electronic components. EMI has the capabilities of interrupting the quality of the sound one hears when tuning in to their favorite radio channel, and it has the potential to muddle the clarity of phone calls on mobile devices. If you are in the process of designing and releasing new electronic gadgets to market, then you will want to work with an EMI shielding company in the US that can ensure that your products offer the best user experience with no interruption in the quality of performance.

EMI is the amalgamation of signals from one electronic system to another.There are three parts to orchestrating an EMI: it’s source, path, and the receiver (the source and receiver are the two systems). Signal coupling occurs at the source and is done through these four methods:

- Capacitive EMI – When there is a system with close proximity, capacitive EMI can happen, and this generally happens in a space less than a wavelength apart. Within this miniscule space parasitic capacitance is formed and this is where an electric charge is housed and sent through charge differentials.

- Capacitive EMI – When two conductors are within a system that has them in close proximity, capacitive EMI can take place. The space enables a parasitic capacitance where electric charge is kept and sent via charge differentials, which are created by the electric fields created by the conductors, and this opens up a path for transferring orphan signals.

- Magnetic EMI – Thus occurs when a signal transfer creates currents across other conductors via electromagnetic induction in which the conductor oscillates or changes.

- Conductive EMI – When there is a conductive path between two circuits, this can occur in common mode or differential mode. In common mode the current travels through grounding in the same direction, and in differential mode the currents travel in opposing directions through lines free from the ground.

- Radiated EMI – This occurs in the open space between the receiver and source. The source releases a wave that gets transmitted over to a circuit.

It is critical to have an EMI shielding company implement this technology into your products to ensure that no electromagnetic interference will compromise the user experience and functionality of your electronic devices.

Popular Types of EMI Shielding

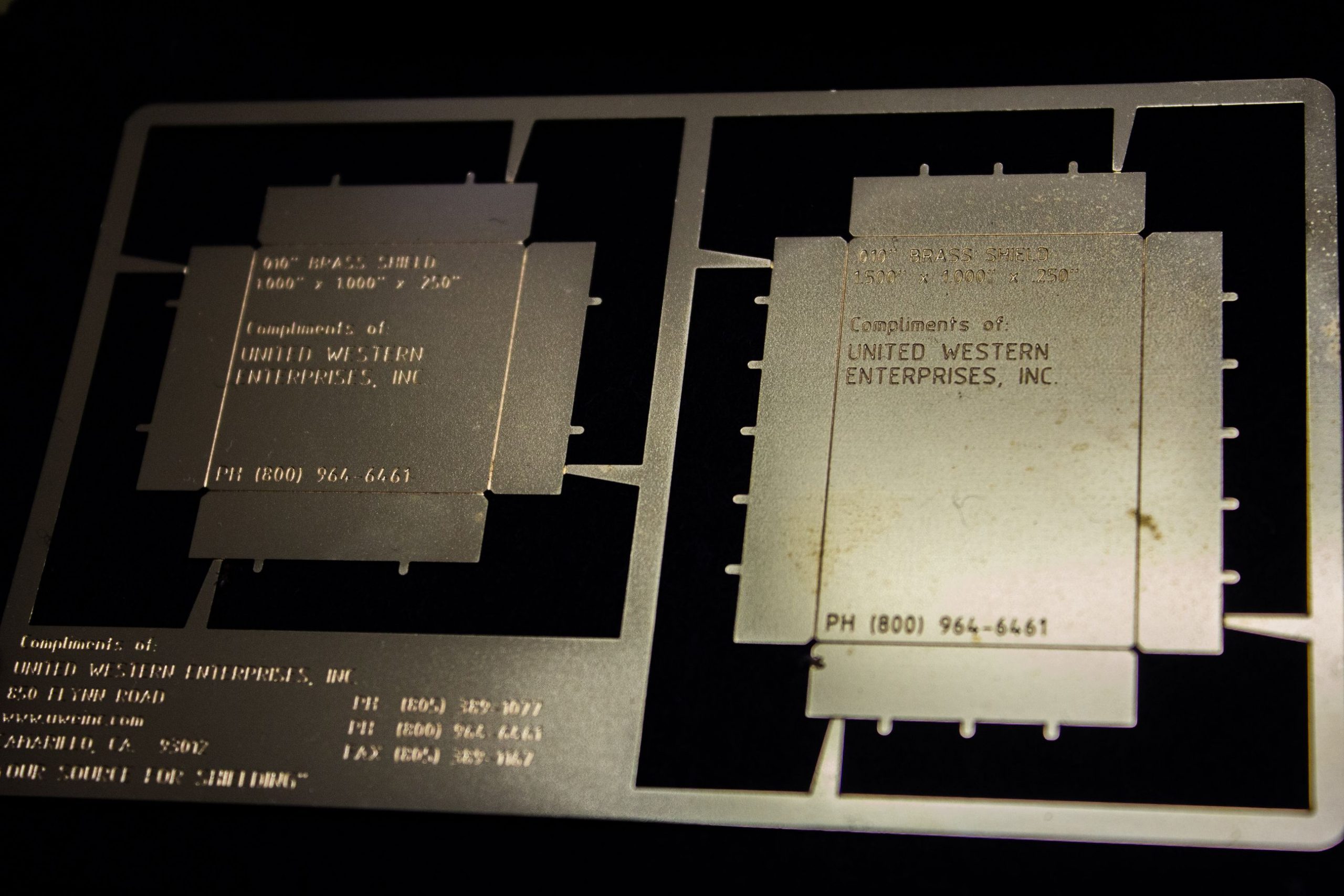

EMI shields can be customized, and come in a wide variety of sizes, shapes, and construction materials. United Western Enterprises has engineered EMI shielding made from brass, steel, stainless steel, nickel silver, and many other materials. Here are three of the most common EMI shielding types we design:

- Gaskets – These are made from metal sheets to fit electric enclosures. These metal screens are usually flexible to prevent deformation and therefore the leaking of electrical circuits. The application will dictate the type of shielding. For example, metal wires and foams may be incorporated, and coatings can be used as necessary.

- Particle Filled Silicone – When EMI shields are designed to protect touch screens, the shield must be soft to prevent any interference from the functionality of the screen when users touch it and engage it. Nickel-graphite silicones are a favorite because they are less expensive than other options, yet they are robust enough to meet military requirements.

- Board Level Shielding – In order to isolate board level components while limiting electromagnetic interference, the board level components in circuit boards must be isolated.

When looking for EMI shielding providers, you will want experts spanning a wide range of industries that can collaborate with your internal team to determine the right kind of EMI shielding required.

EMI Shielding Prevents Disruptions from the Natural Environment

Not only do sources of EMI come from signals that emit from various electronic devices, EMI also comes from environmental sources such as lightning strikes, the earth’s magnetic field, and solar magnetic storms. These sources can impact power quality, but when devices are properly outfitted with EMI shielding components, electronic products will run and perform flawlessly.

Call United Western Enterprises for a Free Consultation Requiring Your EMI Shielding Needs

For decades, United Western Enterprises has been designing and producing the best EMI shielding components for industries that include our armed forces, defense, aerospace, the medical field, and general consumer electronics. All operations are performed in-house based in California, and our teams work around the clock to get your project completed on time, and within budget. Call today and learn whyUnited Western Enterprises is the leading provider for EMI shielding technology services.