Why Brands Invest in Photochemical Etching for Mixed Material Products

May 2022

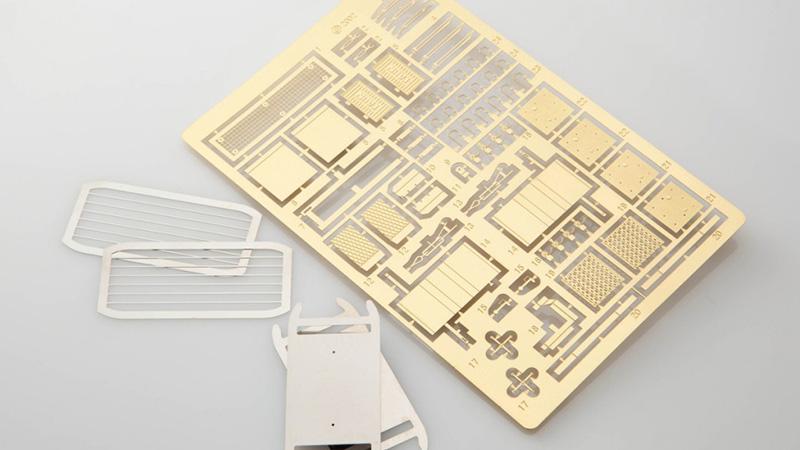

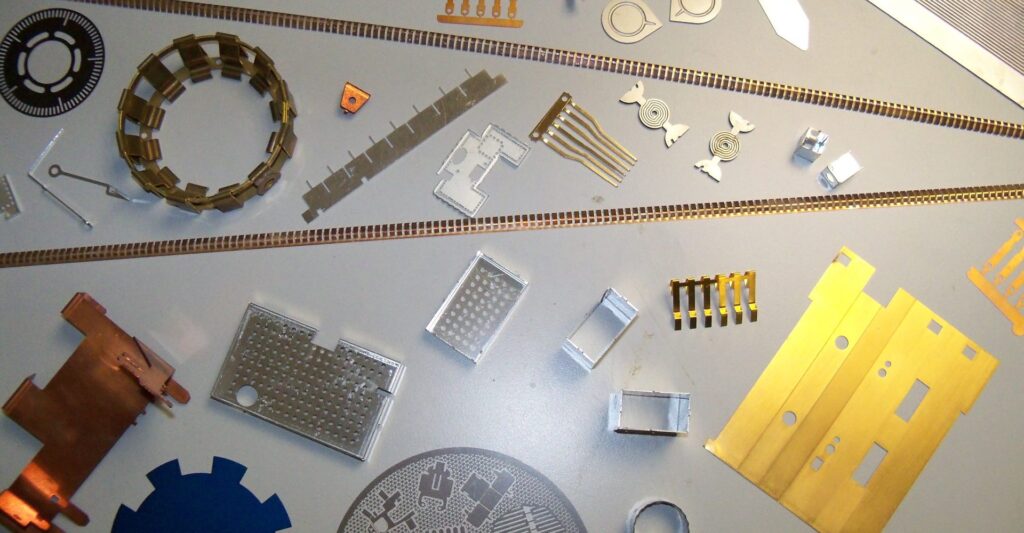

Photochemical etching is a manufacturing process used by brands that require thin metal parts that require precise measurements and intricate designs. There are several reasons why brands using mixed materials invest in photochemical etching, and these reasons range from production cost to flexibility, time, and quality. This article is intended to help those new to leadership roles within their organizations who work with internal design and manufacturing teams learn why the best photochemical etching services are advantageous to improve product quality and organizational growth.

Mixed Materials and Photochemical Etching

Many products use a wide range of materials. From clocks to musical instruments, and from medical equipment to airplane parts, certain products combine materials like wood, plastic, glass, and composites with a wide range of metals. When hard and softer materials adjoin together, dimensions must be just right to get the right fit and performance. Since photochemical etching is the best manufacturing process for creating thin metal parts that can be integrated into other products, manufacturers experienced at shopping the various options will almost always invest in photo etching.

Photochemical Etching Can Enable Lower-Range Thickness

Photochemical etching is arguably the best manufacturing process to create metal parts with a lower-range thickness. For most types of metal alloys, the average etch rate is from 0.0005 to 0.001 inches per minute, on both sides. There is a plethora of products that require metal applications requiring such a scale, so to capitalize on the benefits, brands will invest in photochemical etching to increase part usability and flexibility. Just remember that the sheet size and plan must be consistent with every part’s dimensional tolerance and size.

Photochemical Etching Reduces the Chance of Flaws

With some manufacturing processes, such as laser-cutting, metal pressing, and CNC machining, extreme heat or stress can risk a thin metal part getting stress for heat fractures. In addition, these manufacturing processes can leave metal edges and surfaces with burrs. Photochemical etching, however, does not generate extreme heat or pressure, and all unwanted components are etched away leaving only smooth, perfect edges and surfaces. Not only does photochemical etching, for this reason, help keep costs down by not having to reproduce parts due to errors, but it also speeds up productivity due to its high pass rate on the first production output.

Photochemical Etching is Cost Effective

When it comes to manufacturing products that combine mixed materials, photochemical etching is a cost-effective way for creating thin metal parts for virtually any retail piece, or specific industry piece. First, unlike machine tooling, photochemical etching doesn’t require interchanging expensive tooling options, and it doesn’t require multiple workers to cut the metal pieces. The process is highly affordable, requires a single worker, and multiple pieces can be chemically etched on a single sheet of metal, saving organizations a great degree of money.

Photochemical Etching Won’t Harm Delicate Materials

When thin metal parts are used in products such as jewelry and clocks, the pieces are usually very delicate and can therefore run a higher risk of undergoing deformities. Other machining processes run a higher risk of harming thin metal parts, especially in our modern age of auto engineering where miniaturization is programmed using computers rather than being left in the care of experienced, careful human hands. Unfortunately, the traditional milling process is sometimes untenable due to the heat or pressure in presswork. For example, when etching springs damage can impact the recoil properties making the product inferior. In some cases when companies manufacture flawed parts, there are massive product recalls that damage a brand’s reputation and cause companies to lose millions of dollars.

Photochemical etching is one of the safest manufacturing solutions for delicate, thin metal parts because the process won’t damage the metal and will only etch away unwanted elements. There isn’t any stress or pressure applied that could damage the thin metal parts, nor is there extreme heat that could warp especially delicate and thin pieces.

Call United Western Enterprises for Photochemical Etching Today

If you are manufacturing products requiring several materials, and one of those is thin metal parts, then photochemical etching is likely the best solution to help you send a superior product to market. United Western Enterprises is known as the best photochemical etching company in the country creating delicate, complex and flawless work with the capabilities to deliver any type of order, across virtually all industries. Call today, tell us about your project, and learn how photochemical etching can help take your company to the next level.