Why Photo Etching Is a Revolutionary Technique for Producing Thin Metal Parts with Precision

November 2023

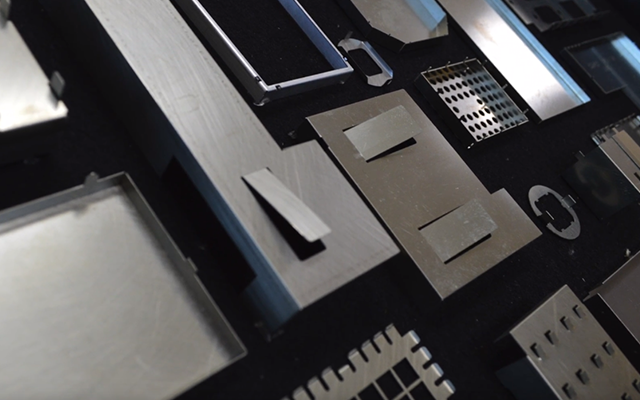

To the average person on the street, it can seem almost miraculous that thin metal parts seen in many different applications can be so intricately and precisely crafted that they look like works of art. How do they achieve such complex shapes and patterns without compromising the quality and functionality of the material? The answer is photo etching, a revolutionary production technique that uses light and chemicals to create thin metal parts with precision.

In this article, we will explain what photo etching is, what its benefits are, and what its future holds.

What Is Photo Etching and Why Is It Important?

Photo etching, also known as photochemical machining or chemical etching, is a process that uses a photoresist (a light-sensitive material) and an etchant (a chemical solution) to selectively remove metal from a sheet or a coil.

The photoresist is applied to the metal surface and then exposed to ultraviolet light through a photomask that contains the desired design. The exposed areas of the photoresist become soluble and are washed away, leaving behind a protective layer on the unexposed areas. The metal sheet is then immersed in the etchant, which dissolves the unprotected metal and leaves behind the desired shape.

Photo etching is a valuable manufacturing technique because it allows for the creation of thin metal parts with high precision and consistency. And it achieves these outcomes without producing any mechanical stress, heat distortion, or burrs on the metal surface.

Photo etching can also create fine features and intricate patterns that are difficult or impossible to achieve with other methods. It can be used for a wide range of metals, such as stainless steel, copper, brass, nickel, titanium, aluminum, and more.

Comparing Photo Etching to Alternative Methods

Forming thin metal parts can be achieved through various techniques, some of which have been used for many years in the manufacturing sector. Yet photo etching has a range of advantages that no other method can equal. Let’s take a look at the ways in which photo etching surpasses alternative fabrication techniques.

- Stamping and Punching – Stamping and punching are forceful processes that can cause deformations such as warping or surface stretching, especially in thin metal. Tooling costs are also fairly high for intricate designs. In comparison, photo etching causes no mechanical stress to the metal and maintains its integrity. Also, tooling is typically less expensive because it uses digital films instead of hard dies.

- Laser Cutting – While laser cutting is precise, it can introduce heat-affected zones (HAZ) that may alter the properties of the metal near the cut. By contrast, photo etching involves no heat, ensuring the mechanical properties of the metal remain uniform throughout.

- Waterjet Cutting – Waterjet cutting can leave a rough edge and might not be suitable for extremely fine features. Photo etching, on the other hand, can create parts with very fine details and smooth edges.

- Fine Blanking – Fine blanking is expensive due to the high cost of the dies and is less adaptable to design changes. Photo etching offers much quicker and cheaper adaptability to design changes as it primarily relies on digital patterns.

- Wire EDM – Wire EDM is slow and generally more expensive, especially for large-quantity orders. Photo etching is faster and more cost-effective for producing high volumes of parts as multiple parts can be etched from the same sheet simultaneously.

- Spinning – Spinning is limited to axially symmetric parts and can be quite labor-intensive. Photo etching allows for more complex and asymmetrical shapes to be produced with little to no variance between parts.

- Roll Forming – Roll forming is confined to uniform cross-sectional profiles. Photo etching allows for variable designs across the metal without the need for multiple stages or roll changes.

- 3D Printing (Additive Manufacturing) – Additive manufacturing processes can be slow and often require extensive post-processing for metal parts. Photo etching is much faster and produces parts with clean, precise edges with generally no need for additional finishing.

Overall, photo etching is often preferred for its precision, ability to produce complex shapes without added cost, lower setup costs, and preservation of the metal’s properties. It is particularly useful for producing large volumes of components with intricate details and tight tolerances, without significant investment in hard tooling. These benefits add up to a truly revolutionary production process.

How Is Photo Etching Evolving and Improving?

Photo etching is a constantly evolving and improving technique that is driven by innovation and technology. Some of the current trends and developments in photo etching are:

- Digitalization – Photo etching is becoming progressively more digitized with the adoption of computer-aided design (CAD) software to create the photomask and computer numerical control (CNC) machines to control the exposure and etching processes. This increases the speed and accuracy of the process.

- Automation – Photo etching is becoming more automated with the use of robots and machines to perform cleaning, laminating, developing, stripping, and inspection processes. This has the potential to significantly reduce the labor costs associated with the process.

- Integration – Photo etching is becoming more integrated with value-added techniques such as electroforming, plating, coating, and welding to enhance the properties and performance of the metal parts.

The continuing evolution of photo etching means that this production process will likely become even more prevalent in the coming years.

Choose UWE for Your Photo Etching Project

If you are interested in learning more about photo etching or ordering your own custom etched products, please contact us today. We are an AS 9100D / ISO 9001:2015 Certified Company that has been providing clients with high-quality photo etched products for over fifty years. Our clients range from aerospace companies to medical equipment manufacturers.

Our team of experienced technicians can handle virtually any design or specification you have. We also have a state-of-the-art facility in Camarillo, California, that can create large quantities of products in a short timeframe. In addition, we offer several value-added options, including laser welding and heat treating, that can augment the strength and functionality of your parts.